鑫景福致力于满足“快速服务,零缺陷,辅助研发”PCBA订购单需求。

First inspection in PCBA processing

The first inspection mechanism refers to the error prevention mechanism to prevent large-scale accidents The first or several products processed on the production line will be processed before the quality production of PCBs or at the beginning of each shift or after the process change Full test After all tests are passed, formal mass production will begin This can reduce the risk of wrong parts, reduce the probability of error, and effectively improve the quality of the entire production This method is the first piece inspection mechanism (FAI). - First ArtICle Inspection)

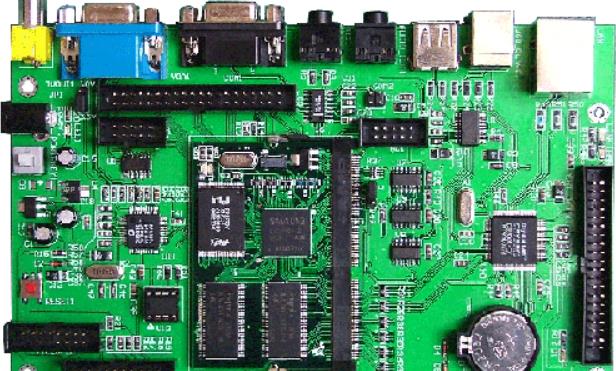

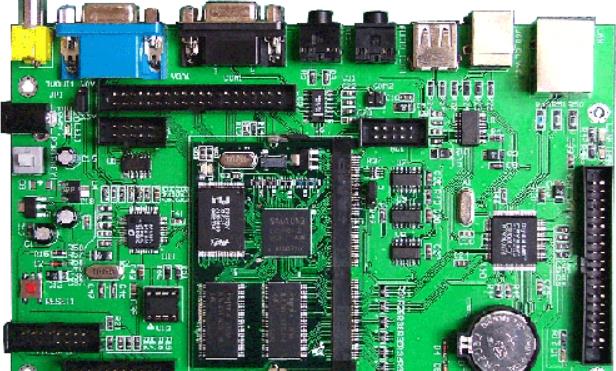

SMT Workshop

First inspection of polychlorinated biphenyls in processing

First article inspection usually occurs in the following situations:

1. New products are launched for the first time

2. Start or handover of each shift

3. Change product model

4. Adjustment equipment, fixture and data

5. Change technical conditions, process methods and process parameters

6. After using new materials or replacing ECN data

First article inspection requirements:

About the first inspection in PCBs processing

1. The products submitted for inspection must first be "self inspected" by the operator, then "mutual inspected" by the team leader or colleagues, and finally "specially inspected" by the inspector. Subsequent products can only be processed after confirmation.

First inspection of polychlorinated biphenyls in processing

2. After the first article inspection, whether it is qualified or not, it shall be approved by the full-time inspector. The inspector shall affix the required MARKs on the first product that passes the inspection and keep it until the shift or batch of products (all first products) are processed. A sample of the product must be retained for comparison with subsequent products to see if the process has changed, and marked with a mark“ ” To indicate that it has passed the first article inspection).

First inspection of polychlorinated biphenyls in processing

3. If the first article is unqualified, find out the cause, take measures, re handle the fault, and conduct three inspections. The first article can be determined only after it is qualified.

Purpose of first article inspection:

First inspection of polychlorinated biphenyls in processing

1. The first article inspection in the production process is mainly to prevent products from out of tolerance, batch repair and scrap. It is a means of pre controlling product production, an important method of product process quality control, and an effective and indispensable method for the company to ensure product quality and improve economic benefits.

First inspection of polychlorinated biphenyls in processing

2. The first inspection is to find out the factors affecting the product quality as soon as possible in the production process to prevent batch defects or scrapping.

First inspection of polychlorinated biphenyls in processing

3. The first product can enter formal production only after passing the inspection, mainly to prevent the occurrence of batch nonconforming products.

About the first inspection in PCBs processing

4. Long term practical experience has proved that the first inspection system is an effective measure to find problems as early as possible and prevent products from being scrapped in batches. Through the first article inspection, it can be found that there are systematic reasons, such as severe wear of tooling or wrong installation and positioning, poor accuracy of measuring instruments, misreading of drawings, wrong feeding or formula, etc. In summary, corrective or improvement measures can be taken to prevent batch failures. Qualified products appear.

The first inspection mechanism refers to the error prevention mechanism to prevent large-scale accidents The first or several products processed on the production line will be processed before the quality production of PCBs or at the beginning of each shift or after the process change Full test After all tests are passed, formal mass production will begin This can reduce the risk of wrong parts, reduce the probability of error, and effectively improve the quality of the entire production This method is the first piece inspection mechanism (FAI). - First ArtICle Inspection)

SMT Workshop

First inspection of polychlorinated biphenyls in processing

First article inspection usually occurs in the following situations:

1. New products are launched for the first time

2. Start or handover of each shift

3. Change product model

4. Adjustment equipment, fixture and data

5. Change technical conditions, process methods and process parameters

6. After using new materials or replacing ECN data

First article inspection requirements:

About the first inspection in PCBs processing

1. The products submitted for inspection must first be "self inspected" by the operator, then "mutual inspected" by the team leader or colleagues, and finally "specially inspected" by the inspector. Subsequent products can only be processed after confirmation.

First inspection of polychlorinated biphenyls in processing

2. After the first article inspection, whether it is qualified or not, it shall be approved by the full-time inspector. The inspector shall affix the required MARKs on the first product that passes the inspection and keep it until the shift or batch of products (all first products) are processed. A sample of the product must be retained for comparison with subsequent products to see if the process has changed, and marked with a mark“ ” To indicate that it has passed the first article inspection).

First inspection of polychlorinated biphenyls in processing

3. If the first article is unqualified, find out the cause, take measures, re handle the fault, and conduct three inspections. The first article can be determined only after it is qualified.

Purpose of first article inspection:

First inspection of polychlorinated biphenyls in processing

1. The first article inspection in the production process is mainly to prevent products from out of tolerance, batch repair and scrap. It is a means of pre controlling product production, an important method of product process quality control, and an effective and indispensable method for the company to ensure product quality and improve economic benefits.

First inspection of polychlorinated biphenyls in processing

2. The first inspection is to find out the factors affecting the product quality as soon as possible in the production process to prevent batch defects or scrapping.

First inspection of polychlorinated biphenyls in processing

3. The first product can enter formal production only after passing the inspection, mainly to prevent the occurrence of batch nonconforming products.

About the first inspection in PCBs processing

4. Long term practical experience has proved that the first inspection system is an effective measure to find problems as early as possible and prevent products from being scrapped in batches. Through the first article inspection, it can be found that there are systematic reasons, such as severe wear of tooling or wrong installation and positioning, poor accuracy of measuring instruments, misreading of drawings, wrong feeding or formula, etc. In summary, corrective or improvement measures can be taken to prevent batch failures. Qualified products appear.

点击

然后

联系

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱