Nowadays, with the increasing functions of various portable consumer electronIC products, the size of PCB is required to be SMAller and smaller. It is inevitable that PCB boards carrying PCB components will also develop rapidly to be light, thin, short and small. Among the test boards, high-density interconnection (HDI) is being used more and more widely. Mobile phone boards, semiconductor packaging substrates, automotive satellite navigation systems and other fields need high-density interconnection circuit boards to support them. Therefore, the demand for High-Density Interconnection circuit boards is growing, and the requirement for the uniformity of copper on the board is also growing. The increase of process difficulty increases the production difficulty, and one link error will cause significant losses. Therefore, the manufacturing of test plates will be carried out before production to reduce the risk of the whole process and improve the plate yield.

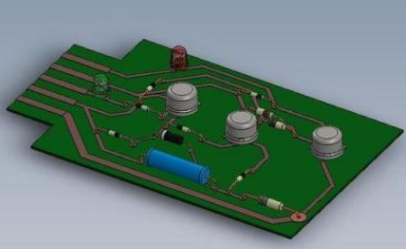

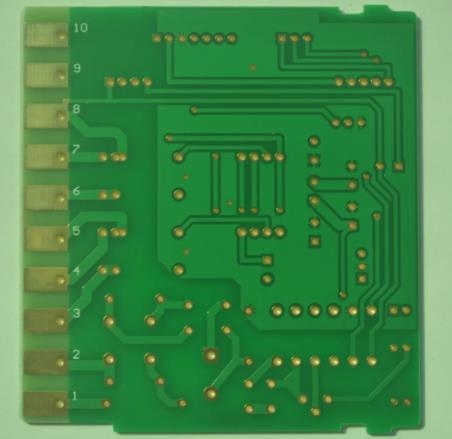

Test board

The copper wire parameters of high-density interconnection circuit boards are one of the standards for evaluating the qualification rate of high-density interconnection circuit boards. As any defect of copper wire will evolve into a defective circuit, and even lead to a series of drawbacks, such as lower yield, higher cost, lower production efficiency, and longer product production cycle, the traditional template for testing the qualification rate of copper wire parameters of high-density interconnection circuit boards has a complex structure and high cost.

CB test board is equipped with multiple test graphic units, and each test graphic unit includes the first test line, the second test line, the third test line and the fourth test line. Since the extension directions of the first test line, the second test line, the third test line, and the fourth test line are different from each other, and do not overlap each other, and the line widths of the first test line, the second test line, the third test line, and the fourth test line are all equal, the set line width standard can be used to judge whether PCB boards prepared using the same PCB process flow are qualified by testing the line widths of test lines in different extension directions. The test structure is SIMple Low cost and easy operation.

Performance Advantages of aluminum substrate in PCB Design

Aluminum substrate is a new type of radiator metal plate. Different from the traditional radiator metal plate, its inherent characteristics can reduce the thermal resistance to the minimum, so as to maximize the EMIssion of more heat and achieve the maximum cooling effect. The aluminum substrate is mainly composed of three parts, namely, circuit layer, insulation layer and metal layer. In addition, double-sided boards are used in some high-end aluminum substrate designs, which are rarely used in traditional radiator metal plates. Because most traditional metal plates are used, the disadvantage of multilayer plates is that the heat dissipation effect cannot be maximized, which cannot meet the heat dissipation needs of users

Aluminum substrate

As a new type of heat conduction metal plate, aluminum substrate has been widely used. In home computers, car stereos and our most popular LED lights, their radiator metal plates are all made of aluminum. The application of aluminum substrate in many fields must be attributed to its own advantages, so what are its high-quality characteristics? The data compiled by the small editor are as follows:

The surface of aluminum substrate adopts a special technology - surface mounting. Through this technology, it can maximize the heat generated by the product during the heat dissipation process or PCB circuit to achieve the best heat dissipation effect.

One of the characteristics of aluminum substrate is that it can not only minimize the product temperature, but also ensure that the use efficiency of the product will not be reduced because it would not pay to reduce the product use efficiency. In addition, aluminum substrate can extend the service life of PCB products to a certain extent.

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱