Quality Management of Multilayer Circuit Board

As the carrier of electronIC components, multilayer circuit poles are used to integrate the aldehyde function of quICk junction components. Therefore, if the circuit board is abnormal, the electrical products cannot operate normally. In order to maintain the normal functionality of the product, the quality of the road board is_ Reliability control is very important.

For different products of Bezhao, how to effectively control the quality and maintain the due reliability must be achieved through technical improvement, material development and the quality control system of the overall manufacturing engineering. The quality control operation must start from the supplier control and village material purchase inspection. The variation control of the production procedure and the operation maintenance of the production line must be _, In addition to online quality inspection monitoring and finished product buried control, the digital manufacturing project can be carried out systematically and stably, so that good products and stable reliability can be established.

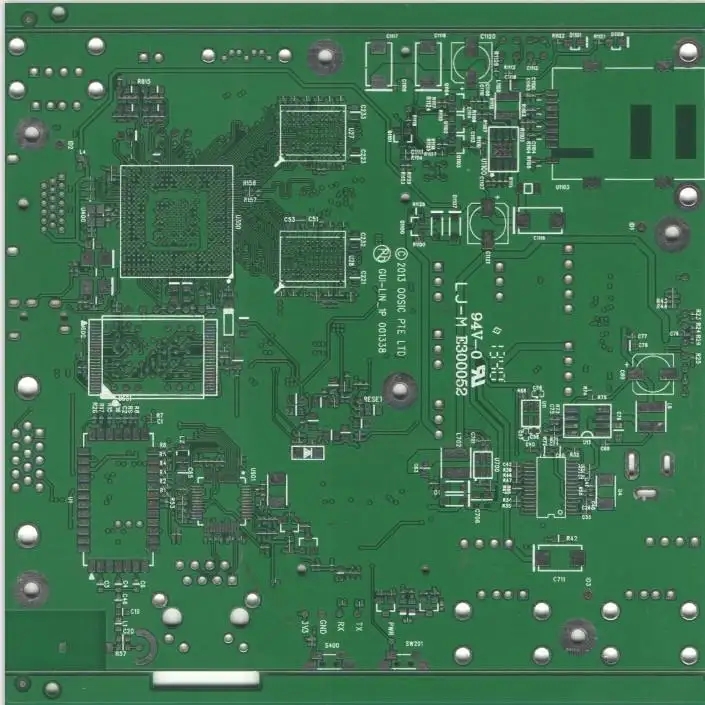

Many quality problems have actually been decided in the design. Although the main consideration in the design stage is the electrical performance and structure of the circuit board, the design will affect the manufacturing difficulty and yield, especially the allowable tolerance. Therefore, how to effectively use the data of manufacturing capacity to design appropriate product structures and appropriate production procedures has become an important element of good product design.

When manufacturing circuit boards, in addition to following various public specifications, different customers will set individual specifications for their products. In particular, the circuit board will change due to different materials and process conditions, and the allowable error range will be specified in the product specifications. No matter between individual products or batches, customers hope that the variation can be controlLED within a SMAll range, but the stricter the specification, the lower the yield. The manufacturer and the customer must pay special attention to how to coordinate acceptable specifications. Excessive design may not be beneficial to buyers, and loose specifications will not be accepted by users. Clearly defining the appropriate scope of acceptance can avoid many unnecessary problems in the future.

1 General quality assurance items

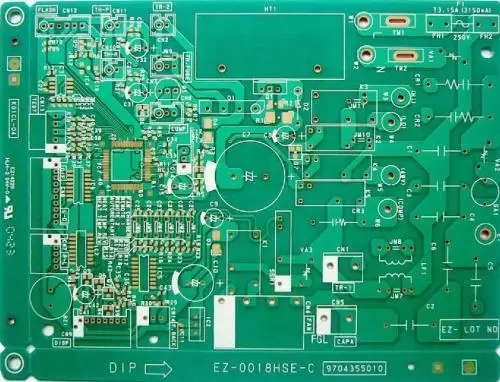

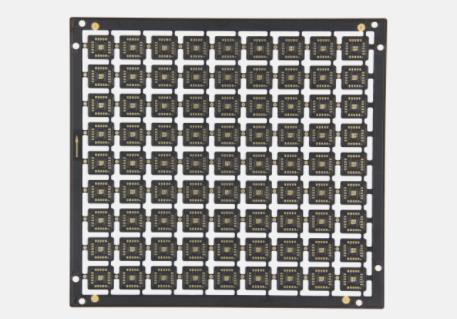

The important quality of electroplated through hole printed circuit board and high-density laminated circuit board is shown in Figure 1.

Non destructive inspection can be carried out for the listed items, and microsection section inspection can be carried out when necessary, which is aimed at the items that must use destructive inspection.

In terms of overall reliability, thermal shock test (thermal shock test, humidification test, etc.) must also be carried out to observe the possible assembly and environmental reliability risks of future finished products by means of accelerated testing.

The level of product quality requirements will be determined according to different test models. These test specifications should be formulated at the product design stage, so that appropriate materials and production technologies can be selected to achieve the quality objectives set for the product.

The overall quality control system is very important when implementing the quality assurance of circuit boards. The basic components of the system should include:

Incoming inspection (IQC, or incoming quality control), in-process inspection (IPQC, or in-process quality control), finished product inspection (FQC, or final quality control), reliability test, etc. The implementation and record of these items must be strictly implemented.

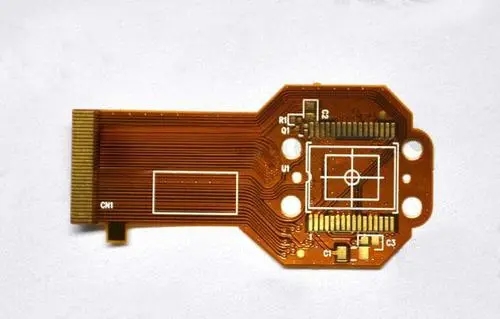

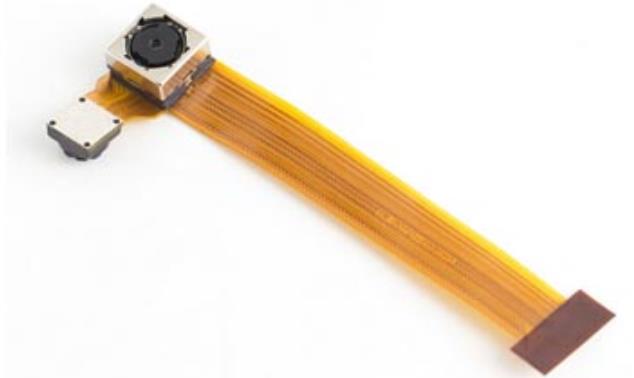

The assembly density of electronic equipment is increasing year by year. With the popularization of surface bonding, the application fields of array small package (such as BGA-CSP) assembly and bare chip assembly have shown a general trend. In response to this trend, in terms of electroplated through hole multilayer circuit boards and high-density multilayer circuit boards, in addition to the variety of structures, the specifications, materials and processes have also become diversified.

The main technical changes, such as: circuit miniaturization, microporosity, thin dielectric layer, reduced circuit thickness, and new materials used in different manufacturing processes, have all changed dramatically. In response to these rapid changes in product structure, quality assurance requires a more rigorous and thorough approach. When establishing the quality management system, all quality assurance processes must be an important part of quality control, starting from the control of incoming materials to the inspection of outgoing goods. Because the circuit board may have potential defects that cannot be checked externally, it becoMES another way of quality assurance to probe the test piece or test circuit (Coupon) to perform reliability test regularly.

The design has a decisive impact on the production of products. At the beginning of PCB design, we must try to SIMplify the program. When making production tools, we should take the compensation value into account for the due specifications of the circuit board. For the design that is allowed by the product but helpful to the production (such as: the uneven density of the circuit can be added with a fake copper pad to evenly distribute the current), we should try to add it, so that it will be conducive to the smoothness of production.

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱