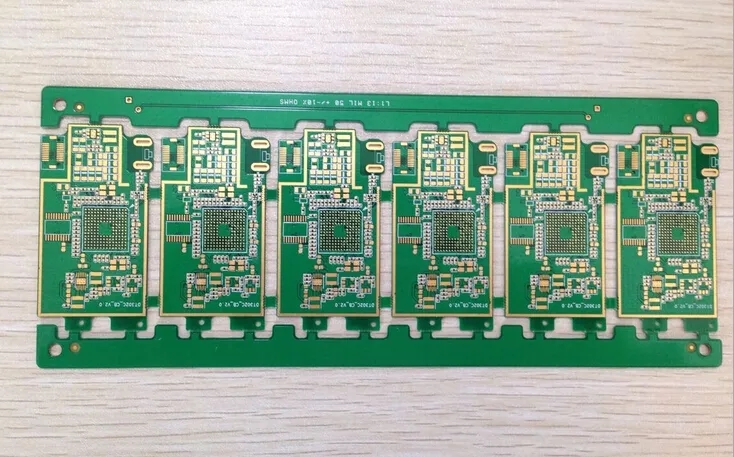

Circuit board factory: summary of processing diffICulties of high-frequency boards

Circuit board manufacturer, circuit board designer and PCBA processing manufacturer explain Circuit board factory: summary of processing difficulties of high-frequency boards

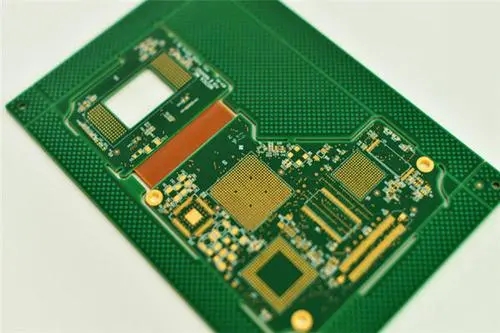

Based on the physical and chEMIcal characteristics of the high-frequency board PTFE, the processing technology of the high-frequency board is different from the traditional FR4 process. If it is processed under the same conditions as the conventional epoxy resin glass fiber copper-clad board, qualified products cannot be obtained.

High frequency plate processing and drilling: the base material is soft, and the number of drilLED laminated plates should be SMAll. Generally, 0.8mm thick plates should be stacked in two; The speed should be slower; To use a new drill bit, the tip angle and thread angle of the drill bit have special requirements.

2. Print resistance welding: After the high-frequency plate is etched and before the print resistance welding green oil, the plate cannot be polished with a roller brush to avoid damaging the base plate. Chemical surface treatment is recommended. To achieve this, it is not easy to make the circuit and copper surface uniform and consistent without grinding the plate, and there is no oxide layer.

3. Hot air leveling: based on the inherent performance of fluororesin, it is necessary to avoid the rapid heating of high-frequency plates as much as possible. Before tin spraying, it is necessary to preheat at 150 ℃ for about 30 minutes, and then spray tin immediately. The temperature of tin cylinder should not exceed 245 ℃, otherwise the adhesion of isolated pads will be affected.

4. Milling profile: the fluororesin is soft, and the profile of ordinary milling cutter is very burry and uneven, so the profile needs to be milled with a suitable special milling cutter.

5. Transportation between high frequency board processing procedures: it cannot be vertically placed, but can only be horizontally placed in the basket separated from paper, and it is not allowed to touch the circuit graphics in the board with your fingers during the whole process. The whole process shall prevent scratches and scratches. Scratches, pinholes, indentations and pits of the circuit will affect the signal transmission, and the board will be rejected

6. High frequency plate processing manufacturer etching: strictly control side erosion, sawtooth and notch, and strictly control ± 0.02mm line width tolerance. Check with a 100x magnifying glass.

7. High frequency plate processing chemical copper deposition: The pretreatment of chemical copper deposition is a difficult and critical step in manufacturing high frequency plate. There are many methods for pretreatment of copper deposition, but in summary, there are only two methods that can stabilize the quality and are suitable for mass production of high-frequency boards:

Method 1: Plasma method: the imported equipment needs to inject carbon tetrafluoride (CF4) or argon (Ar2), nitrogen (N2), oxygen (O2. This method can obtain satisfactory uniform effect, and batch production is feasible. However, to invest in expensive equipment (about 100000 dollars per machine), there are two famous Plasma equipment companies in the United States: APS and March.

Method 2: Chemical method: add the solution of tetrahydrofuran to form the tetrahydrofuran sodium complex, so that the surface atoms of polytetrafluoroethylene in the pores are etched to wet the pores. This is a classic and successful method with good effect and stable quality, but it is highly toxic, flammable and dangerous, and needs to be managed by special personnel.

high frequency board processing pair ε 3.38 and RogersRo4003 high-frequency substrates have the high-frequency performance SIMilar to that of PTFE glass fiber substrate, and have the characteristics similar to that of FR4 substrate that is easy to process. This is a high heat resistant material with glass fiber and ceramics as fillers and glass transition temperature Tg>280 ℃. This kind of base material drilling consumes a lot of drill bits, so special drilling parameters are required, and the milling cutter is often changed for milling the profile; However, the processing technology of other high-frequency boards is similar, and no special hole treatment is required, so it has been recognized by many PCB manufacturers and customers. However, Ro4003 does not contain flame retardant. When the boards reach 371 ℃, high-frequency boards can cause combustion. The LGC-046 board of the state-owned 704 factory is a modified polyphenylene oxide (PPO) type, with a dielectric constant of 3.2 and a processing property similar to FR4. This product has also been approved for use in China. Circuit board manufacturers, circuit board designers and PCBA manufacturers will explain to you the circuit board manufacturers: summary of the difficulties in high-frequency board processing.

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱