Two methods of automatIC routing for common PCB design

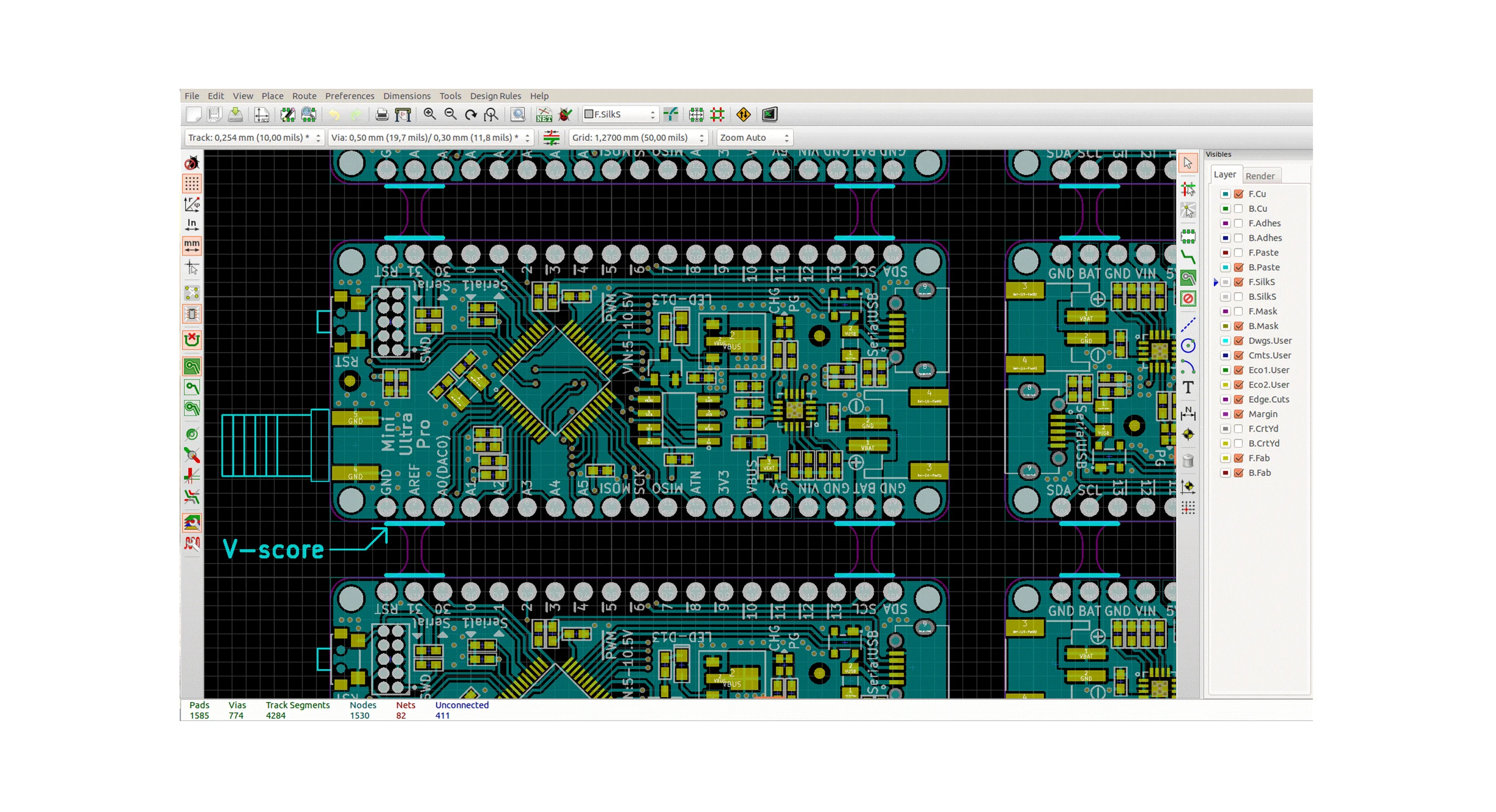

In PCB design, we can see how the benefits of automation are shown when using automatic routing technology Manual routing, which used to be time-consuming and laborious, can now be completed in a few hours using automatic routing tools However, there are two methods for automatic wiring a: PCB design: using standard automatic wiring or automatic interactive wiring We will check automatic routing and automatic interactive routing here to see which method is more suitable for your design Traces on printed circuit boards can be interesting Keep the wiring between pins and avoid obstacles and layer hopping, just like playing a video game If you want to solve problems, becoming a PCB layout engineer is our direction However, when you have to follow specifIC design rules and have to route thousands of tracks in a specific pattern and length, the fun will be reduced The designer needs some help here, and this help will come from PCB automatic routing The PCB design is the speed of all trace wiring Equally important, the router will be fast enough to compute and handle many situations, which slows down designers' attempts to route manually Autorouter can also handle embedded design rules in the layout database, saving time and setting its own rules as needed They can also perform many other tasks as needed, such as diagonal cut line corners, trim traces, and other tracking and cleaning tasks There are two types of automatic routing available to PCB designers The first is general automatic routing, in which routing is completely controlLED by the router itself, although it is subject to the design rules you set The second is interactive automatic routing, which allows the designer to control the trace direction on the circuit board

PCB board

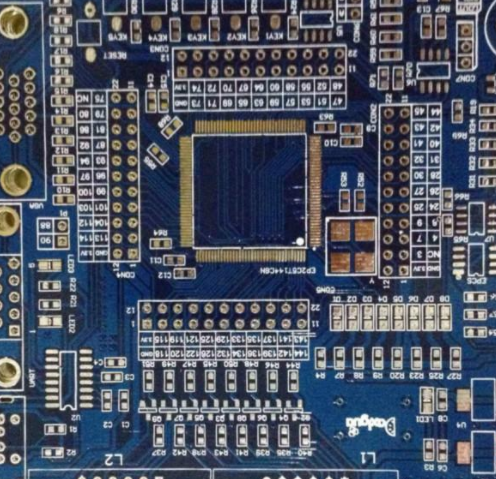

Some details about automatic wiring technology

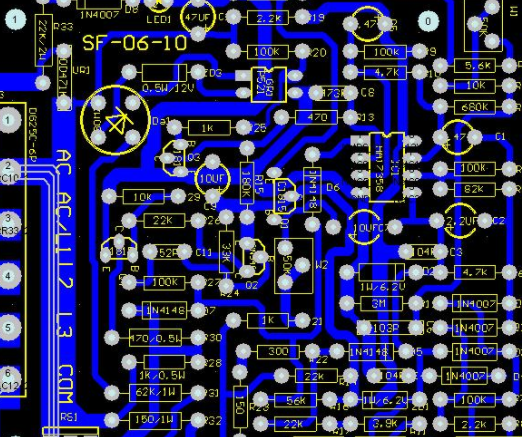

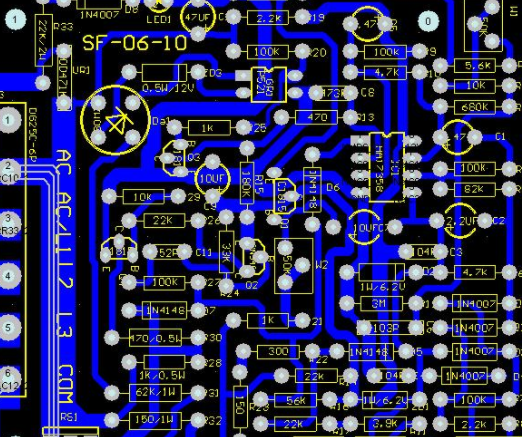

The automatic router that can route the entire circuit board for you is called a batch router. These tools have existed for a long time, and their functions have been growing and enhanced over time. In the past, the final result of batch automatic external connection was more like black box magic, but this has changed. Routing is now predictable and repeatable. These routers are fully configurable and have multiple options that give you the results you need. Today, most batch automatic routing is directly integrated into relevant PCB layout design tools. This allows them to easily use the design rules and constraints that have been set for the board. Although this saves designers a lot of time, routers also have the ability to change these rules. In addition, you can also configure the working mode and routing type of the router. Some of these options include:

Pre wiring: Use this option to route only the escape traces and through holes of surface mount components.

Wiring: This includes routing the entire circuit board in full batch, or routing the selected network only by running the automatic routing program several tiMES.

Clear: This removes loops and stubs that may be left over during auto route.

After routing: This option is used to merge other routing functions, such as masks or test points.

Automatic routing is a good tool, which can be used and save a lot of time. However, you need to note that the pattern of results is basically orthogonal. Although this is useful for some types of networks, it is not necessarily a way to route tight bus tracking for memory routers. To this end, we will introduce automatic interactive routers. Modern PCB automatic router has many rules and contents that can be set for design.

How is automatic interactive routing different?

Automatic interactive routing still uses the function of automatic routing engine, but uses it and PCB board to guide the layout designer of routing path This is achieved by providing designers with virtual canvases, where they can set the parameters and directions of the routes to be completed A good example of the working principle of automatic interactive wiring in PCB design: First, grids are organized into bundles for operation as a group in the design With the Constraint Manager in Allegro, networks can be easily selected through their groups and assigned to harnesses from schematics or layouts Once a bundle is created, you can attach the routing content to it, switch the pins, and adjust the routing layer as needed Next, manipulate the bundle as needed to implement the routing flow required by the designer This allows designers to navigate conflict areas around bundles, such as connectors or tight component placement Once the binding is in place, the designer can straighten out the twisted connections into the pins This can be done by repositioning the bale, swapping pins, or changing layers Convert the beam to a conventional etch path as part of the finished product design database Automatic interactive routing enables designers to manually create the tight routing mode required by DDR or other router technologies, with the speed of automatic routers In addition, automatic interactive routers can be used for high-speed tracking, adjustment and other route clearing tasks The fact is that both types of automatic routers are important, depending on the type of route you need to complete We can see that the routing efficiency of DDR memory bus is higher when using automatic interactive routing However, when the DDR wiring is completed, there are still many loose wires to connect. An ordinary batch processing router will be your friend, especially when cleaning the route It is also very convenient to use standard routers, which can quickly access point-to-point routing and avoid tedious manual routing PCB

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱