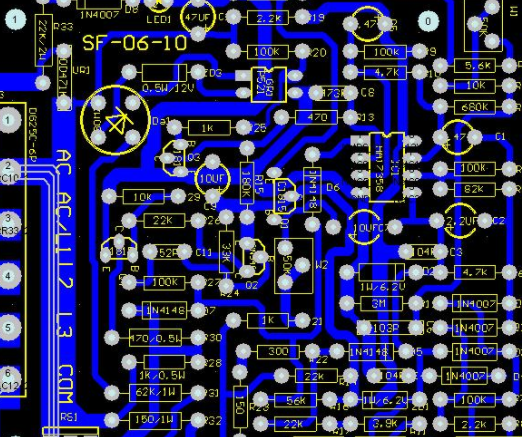

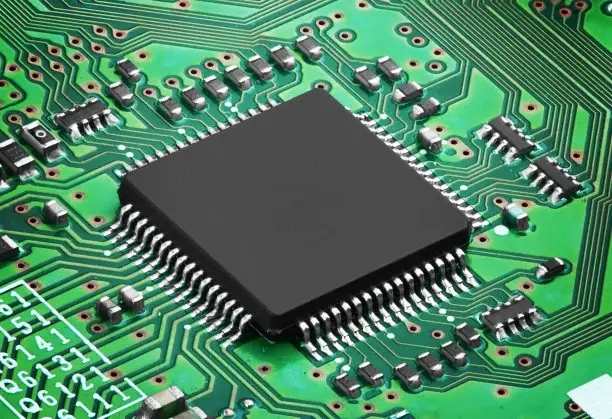

What does the PCB manufacturer mean by PCBA test?

PCBA testing is to develop a robust testing strategy for large, high-density printed circuit board assembly (PCBA) to ensure compliance with the design and function.

PCBA testing is to develop a robust testing strategy for large, high-density printed circuit board assembly (PCBA) to ensure compliance with the design and function. In addition to the establishment and testing of these complex assemblies, the money invested in electronIC parts alone may be high - up to $25000 when a unit is finally tested. Because of this high cost, finding and repairing assembly problems is now even more important than it used to be. Today's more complex assembly is about 18 square inches, 18 layers; There are more than 2900 elements on the top and bottom surfaces; It contains 6000 circuit nodes; More than 20000 welds need to be tested.

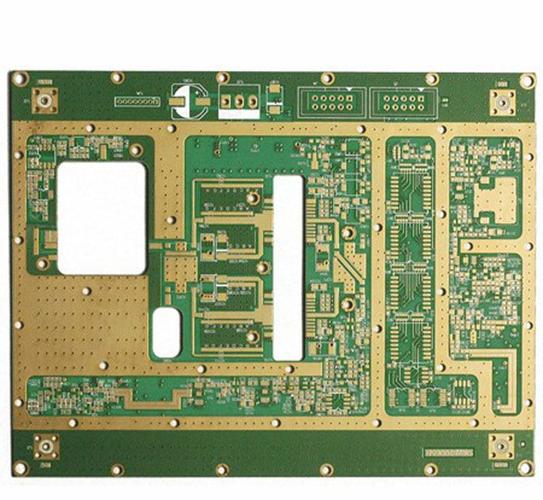

With the increasing labor cost and higher quality requirements, the way of circuit board testing has also changed. At present, functional testing is mainly divided into the following categories

1、 Manual test fixture

Manual test fixture is to use bakelite and acrylIC to make a needle plate, to lead out the input, output and power supply of the plate to be tested, and use manual to SIMulate the input and confirm whether the output is correct.

Features: low price, more manpower, slow testing efficiency, incomplete testing products can not be guaranteed

2、 Single chip microcomputer control function test

Make clamp lock fixture or pneumatic fixture, and then lead out the probe. Connect the input, output and power supply to the circuit of the single chip microcomputer, and let the single chip microcomputer automatically run the test program to simulate the input, and measure whether the output is correct.

The functional test fixture of single chip microcomputer mainly includes the following parts:

1. The test fixture extends the input and output interfaces of the product.

2. MCU control board: judgment of the whole test process and test value. Input and output control. display control

3. Signal source board: provide various signal sources required for testing

4. Relay board: switch various inputs and outputs

5. Measuring board: measure the output part of the product, and judge whether it is good or not

6。 Display module: display test results and test status, usually LCD and nixie tube

Features: SCM function test price is moderate, test efficiency is high, test quality is good, and human intervention is less. However, the versatility is not strong. Generally, only one model can be equipped with one fixture

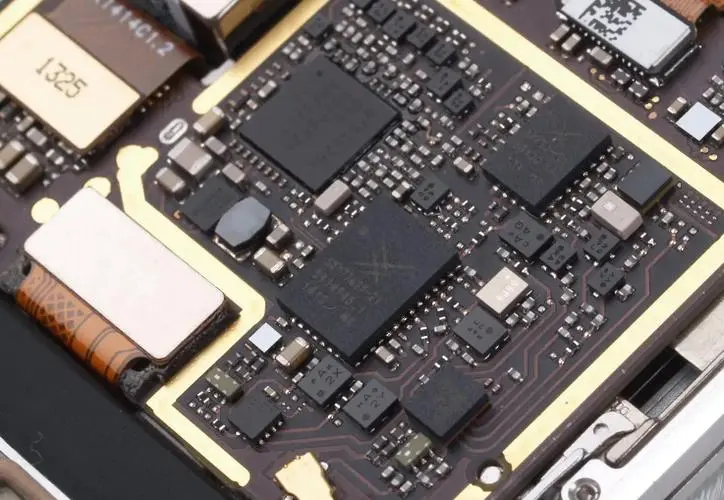

3、 Computer controlLED test system

Use pneumatic or automatic testing institutions on the production line to test the quality of products through computer control.

characteristic:

Computer controlled test fixture

The price is expensive, the test speed is fast, and it does not require human intervention. It is fully automatic. Good universality, similar products can be used universally.

circuit board manufacturers and circuit board designers will explain to you what PCBA testing means.

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱