IdentifICation of aluminum substrate and its difference from FR4 plate

With the continuous promotion of LED industry, LED lighting industry has become one of the important industries for energy conservation and EMIssion reduction? Here are four tips to help you.

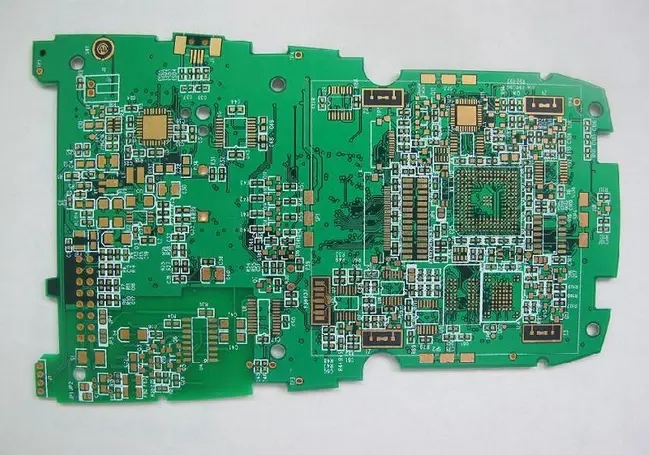

Appearance, whether there is scratching dew copper on the front of the product, whether the ink used is inferior, and whether it is prepared according to the proportion of the ink.

2. Line, what is the thickness of copper platinum in the line of this product? Whether the circuit of the product is pressed with other metals or not determines that the product is unable to withstand the current.

3. Insulation layer: what kind of resin or other insulation layer is used for the insulation layer of the aluminum substrate product, and what kind of insulation layer determines the thermal conductivity of the product. What is the insulation thickness of the product? The withstand voltage of different insulation layers is different.

4. Aluminum, the thickness of the aluminum in this product, whether the aluminum is pure, whether it is anodized, the purity of aluminum is different, the heat dissipation coefficient is also different, whether it is corroded by etching water in production, the circuit board is not only a circuit, but also determines how long the product can be used and whether it is safe, just like human blood vessels.

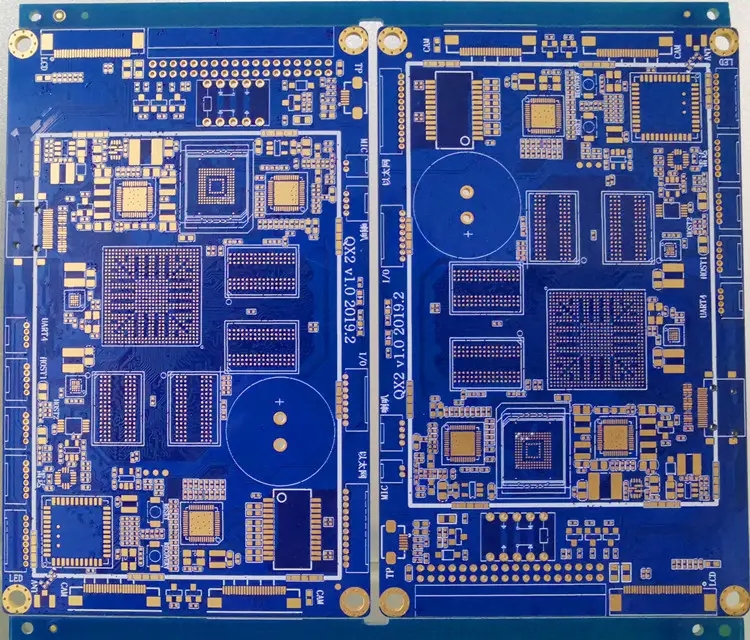

PCB aluminum substrate is composed of circuit layer, thermal insulation layer and metal base layer. The circuit layer (i.e. copper foil) is usually etched to form a printed circuit, so that each component of the component can be connected with each other. Generally, the circuit layer is required to have a large current carrying capacity, so a thicker copper foil, generally 35 thick, should be used μ m~280 μ m; The thermal insulation layer is the core technology of PCB aluminum substrate. It is generally composed of special polymers filled with special ceramics. It has SMAll thermal resistance, excellent viscoelastic properties, thermal aging resistance, and can withstand mechanical and thermal stresses. The metal base is the supporting component of aluminum substrate, which requires high thermal conductivity. Generally, aluminum substrate can also be used, and copper plate (which can provide better thermal conductivity) is suitable for conventional machining such as drilling, punching and cutting. Compared with other materials, PCB materials have incomparable advantages. Suitable for SMT process of power module surface mounting. No radiator is needed, the volume is greatly reduced, the heat dissipation effect is excellent, and the insulation and mechanical properties are good.

What is the difference between aluminum substrate and FR4 plate?

Comparison of main characteristics between aluminum substrate and FR-4 board: comparison of heat dissipation (expressed in saturated thermal resistance) between aluminum substrate and FR-4 board: the base materials are aluminum substrate and PCB with transistors on FR-4 board. Due to the different heat dissipation of the base materials, the operating temperature rises with different test data.

1. Performance:

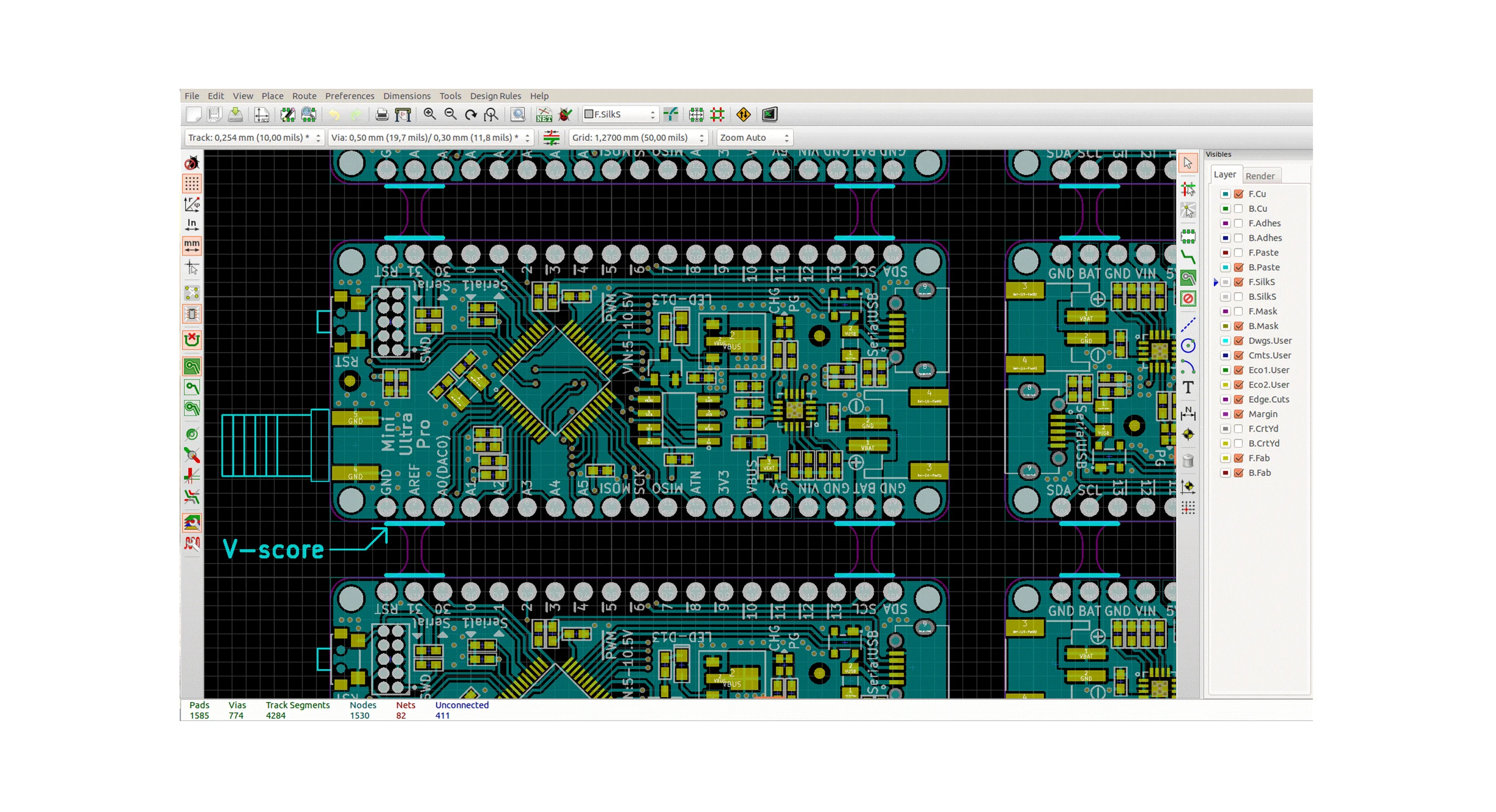

See Figure 1 for the comparative relationship between the conductive circuit (copper circuit) and the fusing current on different substrate materials. From the comparison between the aluminum substrate and the FR-4 plate, due to the high heat dissipation of the metal substrate, the fuse current of the wire is significantly improved, which shows the high heat dissipation characteristics of the aluminum substrate from another angle. The heat dissipation of aluminum substrate is related to its insulating layer thickness and thermal conductivity. The thinner the insulation layer is, the higher the thermal conductivity of aluminum substrate is (but the lower the withstand voltage is).

2. Machinability:

Aluminum substrate has high mechanical strength and toughness, which is superior to FR-4 plate. Therefore, large area printed boards can be manufactured on aluminum substrates, and components with large weight can be installed on such substrates.

3. Electromagnetic wave shielding:

In order to ensure the performance of electronic circuits, some components in electronic products need to prevent electromagnetic wave radiation and interference. The aluminum substrate can act as a shielding plate to shield electromagnetic waves.

4. Thermal expansion coefficient:

The general FR-4 has the problem of thermal expansion, especially the thermal expansion in the thickness direction of the plate, which affects the quality of the metallized hole and the circuit. The main reason is that the thermal expansion coefficient of the raw material thickness direction of the plate is different: the thermal expansion coefficient of copper is 17 × 106cm/cm • ℃, FR-4 plate base material is 110 × 106cm/cm • ℃, there is a large difference between the two, which is easy to occur: the difference in the expansion change of the heated base material causes damage between the copper wire and the metallized hole, which affects the reliability of the product. Thermal expansion coefficient of aluminum substrate is 50 × 106cm/cm • ℃, smaller than the common FR-4 plate, and closer to the thermal expansion coefficient of copper foil. This is conducive to ensuring the quality and reliability of printed circuit boards.

PCB manufacturers, PCB designers and PCBA manufacturers will explain the identification of aluminum substrate and the difference between aluminum substrate and FR4 board.

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱