Methods for Accelerating Important Factors in PCB manufacturing

ElectronIC equipment occupies a central position in most aspects of our lives. Printed circuit boards (PCBs) are becoming more and more common in today's world In the PCB manufacturing industry, given the key role played by these components in electronic products, it is essential to maintain the highest quality This is helpful for PCB manufacturers to avoid delaying the assembly of final electronic products in the shortest possible time In business, time is money Rapid PCB manufacturing plays an important role in maintaining our business competitive advantage

In this article, we will provide you with seven proven rapid PCB manufacturing technologies. Read on to learn more.

Labor cost

The geographical location of actual production of polychlorinated biphenyls leads to new labor costs. The manufacturing of printed circuit boards requires skilLED manual operation and automatic machinery, which increases labor costs. In this case, manufacturing companies have the motivation to manufacture such panels in places where labor is relatively cheap.

For example, PCBs assembled in South Asia are several tiMES cheaper than PCBs assembled in Western Europe or North America. Assuming the turnaround time is 3 days, the average assembly cost in North America is about US $1100, while that in China is US $545. It is worth noting that overseas manufacturing will drive up costs due to processing, transportation and communication delays.

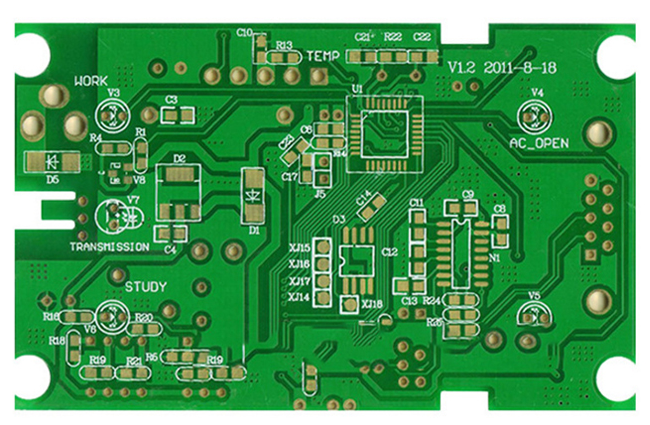

Circuit board

But also, cheap production may bring unpredictable costs, which you must consider before signing contracts with overseas manufacturers.

Implement design for Rapid Manufacturing (DFM)

Designed to improve the manufacturability of PCBs in the design phase Sometimes, the PCB design you want is difficult or impossible to manufacture, so the manufacturer will send it to you for redesign Sometimes manufacturers will try to restructure This process will slow down turnaround time

The solution is to implement DFM. Consider PCB manufacturer's capability and archive requirements in the design phase to avoid potential redesign. At this stage, consultation with manufacturers plays an important role in ensuring manufacturability. Make sure to place datum MARKs to help pick and place the machine automatically.

Own source components

One of the main reasons for PCB delay is that important parts are out of stock when required by the manufacturer. Typically, this happens between creating a BOM and placing a manufacturing sequence. The best way to avoid this is to plan and buy carefully. Try to avoid making changes at the last moment of the supply chain, as this may lead to longer delivery times.

Instead of relying on PCB manufacturers to purchase components for you, consider purchasing them independently. Of course, a fast PCB manufacturer may have a good relationship with several PCB component distributors, but they are sometimes vulnerable to the shortage of parts. The last thing you want is for manufacturers to redesign your boards because they don't have specific areas. You cannot guarantee that the redesigned PCB will accurately meet your requirements. If the product is defective, the turnover time will inevitably increase.

Provide complete archive package

Become a fast and correct PCB service provider. Fortunately, there are all kinds of PCB manufacturing, and PCB companies need a complete file, including the following:

Gerber archives

Borehole archives

Total BOM

Netlist file

Your original CAD file

Centroid data

Assembly instructions

Assembly drawing

If the center of gravity data cannot be sent to the PCB manufacturer, the manufacturing process may be delayed. This is because the data provides specific details about component orientation. Centroid data also links individual components to their reference numbers. Without these basic data, your manufacturers will have to try to find out the key details themselves, which will slow down the whole process.

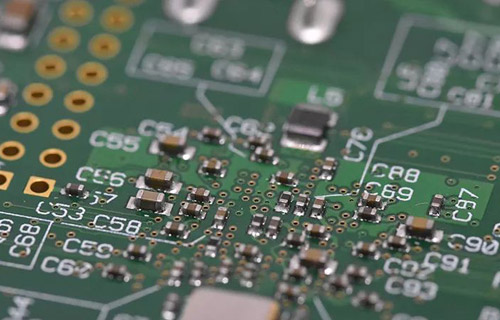

SIMplified design

Most modern circuit boards have multiple layers. Each layer of these boards requires many manufacturing steps, which takes quite a long time. If you can reduce this number of layers, you will eliminate all unnecessary and time-consuming manufacturing steps and reduce PCB turnaround time.

The simplest PCB design involves two layers. Double layer printed circuit boards usually require fewer pressing, etching, electroplating and covering steps. In order to reduce the number of layers, it is necessary to remove the vias and select blind holes and embedded vias.

You can decide to use layer stack design and routing to eliminate certain layers. This will add electroplating steps, but will reduce manufacturing steps.

Adopt advanced technology and system process

Over the years, rapid innovation has emerged in PCB manufacturing. With the progress of science and technology, many aspects of PCB manufacturing technology have been greatly improved. These include:

1. Stronger responsiveness to customer needs

2. Reduce downtime and waste levels

3. Better product design and quality

4. Simplify the relationship between suppliers and customers

5. Enhance customer service delivery

Each of these improvements will help speed up turnaround time. Any company that invests in new technology will usually get better competition and development in today's market. When looking for fast PCB manufacturers, consider those manufacturers that give priority to advanced technology in their processes.

Consider compliance

The most reliable PCB manufacturers ensure that they meet the highest industry standards. PCB manufacturers should be able to provide high quality at every step of the manufacturing process. Every stage or PCB production requires careful attention.

For example, find out if your potential PCB manufacturer meets all the standards of the printed circuit Association. Do they provide RoHS, ISO and UL compliant PCBs to customers?

Only PCB manufacturers that comply with industry standards can ensure the safety, reliability and high performance of their products. Since compliance with industry standards and regulations can improve internal and external communication, this manufacturing process is usually much faster.

On the other hand, companies that do not comply with relevant regulations often have production delays. This is because the final product often fails to meet your expected standards, which requires redesign.

In short

In short, time is a key factor in the production of PCBs When it comes to PCB manufacturing, you must carry out activities that will save time One of the best practices is that PCB manufacturers will do their best to ensure that you get the PCB on time Such manufacturers usually perform the entire PCB manufacturing process through a fast turnaround time frame

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱