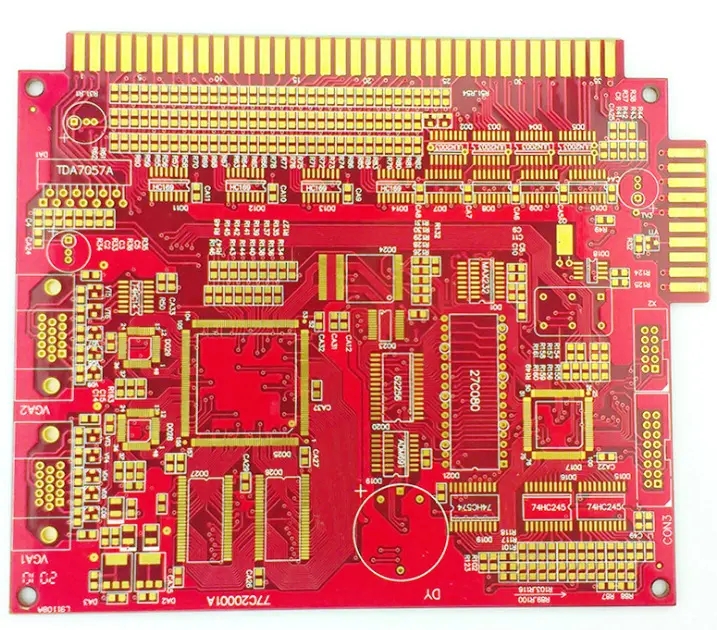

Selection of three proofing paint and varistor for circuit board

The Circuit board manufacturer, circuit board designer and PCBA manufacturer will explain the selection of three proofing paint and varistor for circuit boards

The three proofing paint is a kind of paint with special formula, whICh is used to protect the circuit board and its related equipment from the corrosion of bad environment. Three proofing paint has good high and low temperature resistance; After curing, it forms a transparent protective film, which can protect the circuit from damage under conditions such as chEMIcal substances (such as fuel, coolant, etc.), vibration, moisture, salt spray, humidity and high temperature. Under these conditions, the circuit board may be corroded, mildewed and short circuited. It has excellent insulation, moisture-proof, anti leakage, dust-proof, anti-corrosion, anti-aging, anti mildew, anti loose parts, insulation and corona resistance.

Benefits of three proofing paint for circuit board

1. Protection circuit board

The protective film formed by the three proofing paint on the circuit board can effectively isolate the circuit board and protect the circuit from the corrosion and damage of harsh environment, thus improving the reliability of the circuit board, increasing its safety factor and ensuring its service life.

2. Achieve higher PCB integration

In addition, since the three proofing paint can prevent electric leakage, it allows higher power and closer PCB spacing, thus meeting the purpose of miniaturization of components.

3. Decorate the appearance of the circuit board

Either transparent or colored three proofing paint can improve the appearance of printed circuit board, and the latter can also ensure a higher degree of confidentiality by covering components and design layout.

4. Insulate tin feet between circuit boards to prevent leakage, short circuit and other phenomena

5. Protect the tin spots on the surface of the circuit board from being oxidized by air to make it more beautiful and prevent dust from hindering and affecting the normal operation of the circuit board.

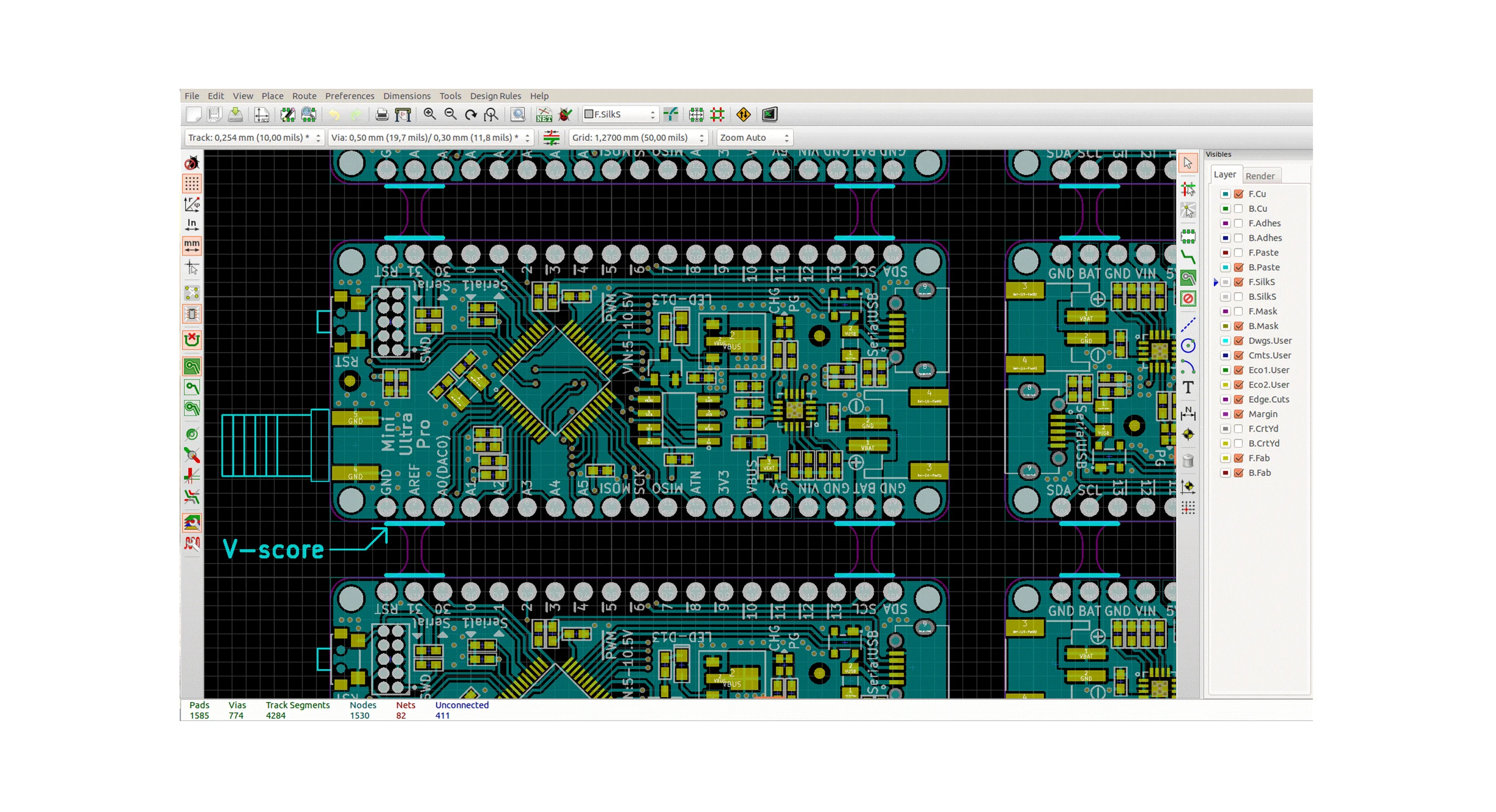

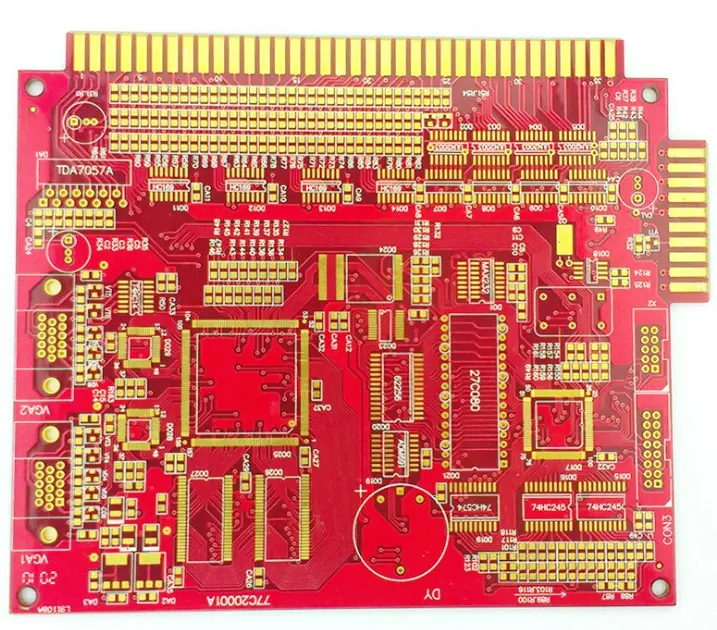

Operation process of three proofing paint for circuit board

1. Brushing - the SIMplest three proofing paint process, which can produce excellent coating effect on smooth surfaces.

Brush Tuotai three proof paint

Brush Tuotai three proof paint

2. Spraying - spraying is the most commonly used coating method in the industry, which can be divided into automatic spraying and manual spraying. Machine spraying can realize automatic feeding, save labor and material costs, improve production efficiency, and ensure product consistency, product quality and surface spraying effect.

3. DIP coating - Dip coating can ensure complete film covering and will not cause material waste due to overspray.

4. Selective coating - coating is accurate and does not waste materials. It is suitable for coating in large quantities, but has high requirements for coating equipment. It is most suitable for film covering in large quantities. Use a prepared XY table to reduce the masking. When PCB boards are painted, many connectors need not be painted. The adhesive tape is stuck too slowly and there is too much adhesive left when tearing. It can be considered to make a combined cover according to the shape, size and position of the connector and use the mounting hole for positioning. Cover the areas not to be painted.

How to select varistor

1. First, 10d471K refers to the voltage sensitive voltage 47 * 10 ^ 1=470V, and K refers to the error+/- 10%,

Similarly, 10d470K means that the voltage sensitive voltage is 47 * 10 ^ 0=47V, and other parameters can be known similarly;

2. For the varistor, the most important parameter is of course the voltage. Any varistor has a curve voltage resistance curve with respect to the voltage applied at both ends. The voltage can be simply understood as the transition voltage. When it coMES to this voltage, the resistance value of the varistor drops sharply and the resistance is very SMAll. Note that the varistor is connected in parallel at the input end of the line to protect the circuit behind. When the resistance decreases sharply, The total circuit current will be very large, which will cause the short circuit protection action of the air switch or circuit, and then cut off the line input;

3. The above is the application and principle of the varistor. Therefore, the varistor is mainly used for overvoltage protection. Selecting different voltage means that it will act under different overvoltage values; (You can simply understand the varistor voltage as the breakdown voltage of the voltage stabilizing tube. After this voltage, the current of the voltage stabilizing tube increases sharply, while the resistance of the varistor decreases sharply, causing the current flowing in the circuit to increase sharply. Circuit protection)

4. In addition, for different varistors, although there is a nominal voltage such as 470V, it is unlikely that each varistor will have an accurate range, which will be given in the manufacturer's parameters,

For example, if you use an AC 24V working voltage, you cannot select 24V as the voltage sensitive voltage, because it is protected and must be greater than 24V. For example, you can select 38V (based on the lower and middle limit of the voltage sensitive range);

5. Of course, the varistor also has many other parameters. You can check the relevant information again. There are many. After understanding the above, you can apply it. PCB manufacturers, PCB designers and PCBA manufacturers will explain the selection of three proofing paints and varistors for PCB.

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱