What are the debugging steps of the PCBA board?

When PCBA patch processing plants encounter newly designed PCBA samples, debugging will be very diffICult When the PCBA board is relatively large and has many electronIC components, it does not know where to start If you master a set of reasonable debugging methods, you can get ideal results in debugging PCBA boards

During the commissioning of PCBA model, the chip processing plant usually follows the following steps: PCBA board surface observation and resistance inspection between power supply and ground wire. As a model for PCBA, SMT technicians should first roughly observe whether there are some appearance problems on the PCBA board, such as cracks, short circuits, open circuits, etc. If necessary, you can check whether the resistance between the power supply and the ground wire is large enough.

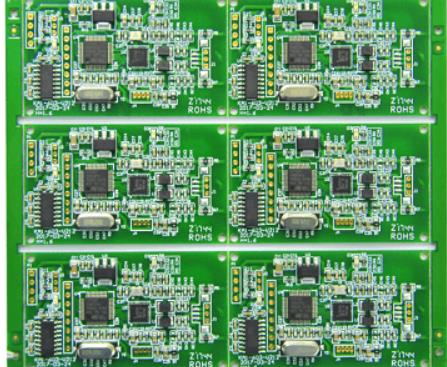

Installation components: components and independent modules are instalLED on PCBA circuit board. Generally speaking, when they can not ensure normal operation, it is better not to install them all at once, but to install them separately in turn, so that it is easy to determine the fault range of PCBA boards.

Polychlorinated biphenyls

Power on to check whether the power supply output voltage is normal Install the power supply unit to the PCBA circuit board, and then power on to check whether the power supply output voltage is normal If you are not sure when powering on, consider using an adjustable regulated power supply with current limiting function

Preset overcurrent protection current: firstly, preset overcurrent protection current, then slowly add voltage value of regulated power supply to monitor input current, input voltage and output voltage. If there is no over-current protection and other problems during upward adjustment, and the output voltage is normal, it indicates that the power supply is normal. Otherwise, disconnect the power supply, find the fault point, and repeat the above steps until the power supply is normal.

Install other modules and conduct power on test: Next, gradually install the PCBA board of other modules on the Power test each installed module After turning on the power supply, please follow the above steps to avoid overcurrent and component burning due to design errors or component installation errors

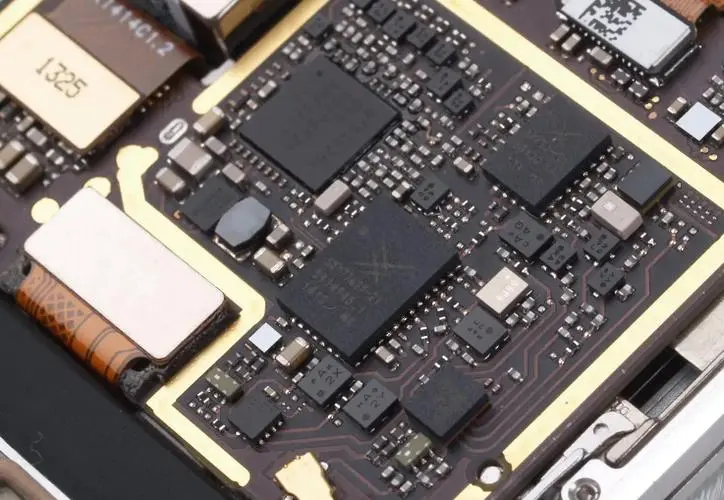

PCBA board manufacturers usually have the following methods to find PCB faults in PCBA manufacturing: voltage measurement method first needs to confirm whether the voltage of each chip power supply pin on the pcb circuit board is normal, then check whether various reference voltages are normal, and whether the working voltage of each point is normal. For example, when the ordinary silicon triode is powered on, the be junction voltage is about 0.7 V, while the CE junction voltage is about 0.3 V or less. If the be junction voltage of the triode is greater than 0.7V (except for special triodes, such as Darlington tubes), the be junction may be open circuit.

Signal injection method of PCB board: add signal source to the input terminal, and then measure whether the waveform of each PCB point is normal in order to find the fault point of pcb board. Sometimes we also use some SIMple methods, such as touching input terminals at all levels with tweezers to see if the output terminals react. This is usually used for audio, video, and other amplification circuits. It should be noted that this method cannot be used for circuits with hot backplane or circuits with high voltage, otherwise electric shock may be caused. If there is no response at the first level before the collision, but there is a response at the second level after the collision, it indicates that the problem is at the previous level, and the inspection shall be focused.

Of course, there are many other ways to find PCB fault points, such as looking, listening, SMElling, touching, etc "Look" is to see whether components on PCB are mechanically damaged by SMT technology equipment, such as cracking, blackening, deformation, etc; "Listening" is to listen to when the working sound is normal, for example, something that should not sound, where it should sound, or the sound is abnormal; "Smell" is to check whether PCB circuit board has peculiar smell, such as PCB circuit board burning smell, capacitor electrolyte smell, etc "Touch" means that SMT technicians use their hands to test whether the temperature of the equipment on the PCB is normal, such as too hot or too cold Some electrical equipment will generate heat when working If they feel cold, they can basically be judged to be ineffective However, if the place that should not be hot is too hot or the place that should be hot is too hot, this is abnormal General purpose power triode, voltage stabilizing chip, etc In this case, it is normal for the temperature PCB to work below 70 ℃ What is the concept of 70 degrees? Try to raise your hands If you can hold on for more than 3 seconds, it means the temperature is about 70 degrees With this kind of pipe, there is no problem

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱