Seven major inspections during PCB production

1. PCB board detection requires LCR measurement

LCR measurement is suitable for some SIMple circuit boards. There are few components on the circuit board, there is no integrated circuit, and only some circuit boards with passive components do not need to be recycLED after the placement is completed. LCR measurement is directly used to measure the components on the circuit board, and compared with the component rating on the BOM. Formal production can start when there is no abnormality.

2. PCB board detection FAI first artICle test

The FAI first article test system is usually composed of a set of LCR bridges led and integrated by FAI software. The product BOM and Gerber can be imported into the FAI system. The employees use their own fixtures to measure the first article sample elements. The system will check with the input CAD data. During the test process, the software will display the results through graphics or voice to reduce the error test caused by the negligence of personnel, which can save labor costs.

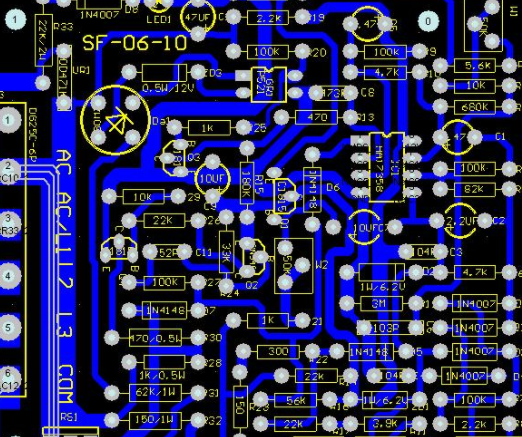

3. PCB board inspection AOI test

OI test, this test method is very common in pcba processing, and is applicable to all PCBA processing. It is mainly used to determine the welding problem of components through the appearance characteristics of components. It can also be used to determine whether there is a wrong component on the circuit board by checking the color of components and the silk screen on the IC.

4. PCB board detection flying pin test

Flying needle test, which is usually used in SMAll batch production of some development properties, is characterized by convenient testing, strong program variability, and good versatility. It can basically test all types of circuit boards, but the testing efficiency is relatively low. The testing time of each board will be very long, mainly by measuring the resistance between two fixed points to determine whether there is short circuit and empty soldering in the total components of the circuit board, Wrong parts.

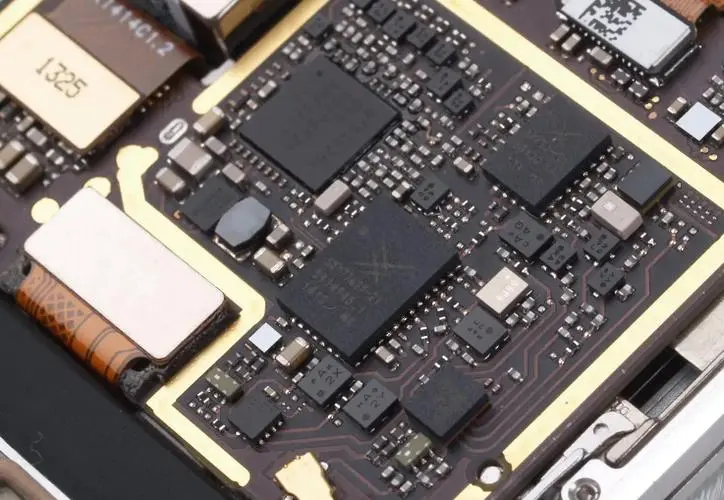

5. PCB board detection X-RAY inspection

X-ray inspection: For some circuit boards installed with hidden solder joints, such as BGA, CSP and QFN packaged components, X-ray inspection is required for the first article produced. X-ray has strong penetrability, and is an instrument most used in various inspection occasions. X-ray perspective can show the thickness, shape, welding quality and solder density of solder joints. These specific indicators can fully reflect the welding quality of solder joints, including open circuit, short circuit, holes, internal bubbles and insufficient tin, and can be used for quantitative analysis.

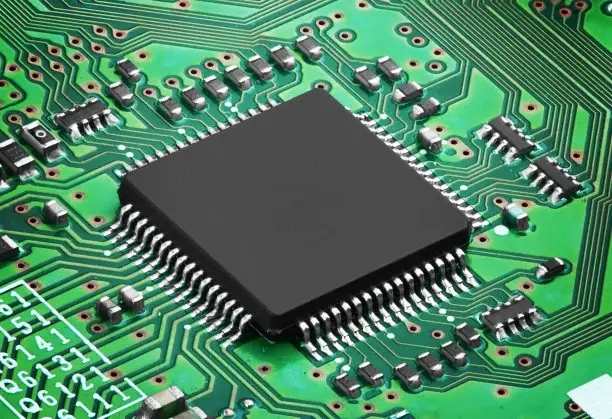

6. PCB board detection ICT test

ICT test. ICT test is usually used for models that have been mass produced. It has high test efficiency and high manufacturing cost. Each model of circuit board needs a special fixture. The service life of the fixture is not very long, and the test cost is relatively high. The test principle is similar to that of flying pin test. It is also used to measure the resistance between two fixed points to determine whether the components on the circuit have short circuit, empty soldering, wrong parts, etc

7. PCB board detection FCT function test

FCT function test, FCT function test is usually used on some complex circuit boards. The circuit boards to be tested must be welded, and the real use scenario of the circuit board must be simulated through some specific fixtures. Put the circuit board in this simulated scenario, and observe whether the circuit board can be used normally after the power is turned on. This test method can accurately determine whether the circuit board is normal.

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱