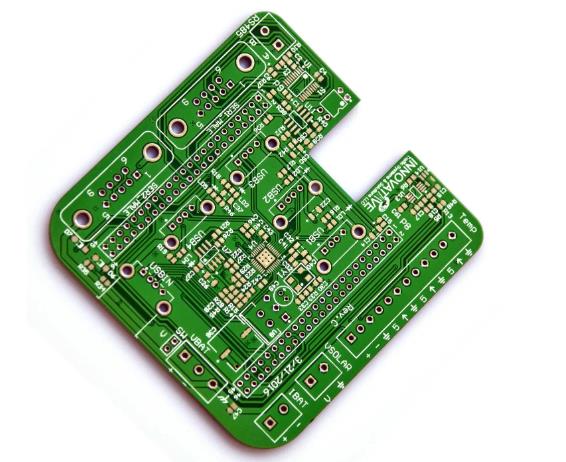

The circuit board manufacturer will explain to you what kinds of common testing equipment are used for PCBA process

SPI can detect the printing quality of solder paste, and can detect the height, area, volume, offset, short circuit, etc. of solder paste. Function of online SPI: real-time detection of solder paste volume and shape. Reduce the defects of SMT production line, feed back the detection results to the solder paste printing process, and timely adjust the status and parameters of the printing machine.

The so-calLED optICal detection is to take photos of the detection elements with an optical lens, and then analyze and detect the photos. AOI automatic optical detector has many places where AOI can be placed in SMT factory, but it is generally placed behind reflow soldering in actual processing to detect the welding quality of PCBA after reflow soldering, so as to timely find and eliminate defects such as less tin, less material, faulty soldering, and continuous tin.

Generally, AOI detection equipment consists of two parts, one is detection equipment, the other is repair equipment. The detection equipment can detect the existence and absence of components, the polarity and characters of components to ensure the accuracy of patch installation. After furnace front mounting: element missing/existing; Offset (X, Y, θ Value); Rotation; Turnover; Side standing; Polarity, etc.

In fact, X-RAY is the X-ray commonly used in hOSPitals. It uses the high voltage impact target to generate X-ray penetration to detect the internal structure and structure quality of electronIC components and semiconductor packaging products, as well as the welding quality of various types of SMT solder joints.

ICT is an automatic online tester with wide application scope and SIMple operation. ICT automatic online detector is mainly used for production process control and can measure resistance, capacitance, inductance and integrated circuit. It is particularly effective for detecting open circuit, short circuit, component damage, etc., with accurate fault location and convenient maintenance.

ICT automatic online tester is a necessary test equipment produced by PCBA (printed circuit board assembly) for modern electronic enterprises. ICT has a wide range of uses, high measurement accuracy, and clear instructions for detected problems. Even workers with ordinary electronic technology can easily handle problematic PCBA. The use of ICT can greatly improve production efficiency and reduce production costs. 2. ICT Test is mainly used to test the open circuit, short circuit and welding of all parts of the PCBA circuit by contacting the test points from the PCB layout with the test probe. It can be divided into open circuit test, short circuit test, resistance test, capacitance test, diode test, triode test, FET test, IC pin test (testjet ` connect check) and other general and special components for missing installation, wrong installation, parameter value deviation, solder joint welding If the circuit board is open or short circuited, tell the user exactly which component is the fault or where the open or short circuit is located. (High recognition ability for welding test of components)

ICT, In Circuit Test, is a standard test method to check manufacturing defects and defective components by testing the electrical performance and electrical connection of online components. It mainly checks the open and short circuit of online single components and circuit networks. It is characterized by simple operation, fast and accurate fault location. It is a component level test method used to test each component on the assembled circuit board

Flying needle ICT basically only carries out static testing, which has the advantage of no need to make fixtures and short program development time.

Needle bed ICT can test the functions of analog devices and logic functions of digital devices, with high fault coverage. However, special needle bed fixtures need to be made for each single board, and the cycle of fixture production and program development is long.

Integrated circuit (IC) automatic testing machine is used to test the integrity of integrated circuit functions, which is the final process of integrated circuit production and manufacturing, to ensure the quality of integrated circuit production and manufacturing.

In the manufacturing process of all Electronic devices, there is a need to eliminate the false and retain the true, which is actually a process of testing. In order to realize this process, various test equipment is required, which is called ATE (Automatic Test Equipment). The electronic component DUT (Device Under Test) mentioned here, of course, includes the IC category. In addition, it also includes discrete components and devices. ATE exists in each link of the front end and the back end, depending on the requirements of the process design.

In the process flow of components, there are various links that need to be tested according to the needs of the process. The purpose is to screen defective products, prevent them from entering the next process, and reduce redundant manufacturing costs in the next process. These links need to be grasped through various physical parameters, which can be light, electricity, wave, mechanics and other parameters in the real physical world. However, most of them are electronic signals. The most important thing that ATE design engineers should consider is the parameters of electronIC parts, such as time, phase, voltage and current, and other basic physical parameters. That's what electronics calls signal processing.

FCT (Function Test) refers to a test method that provides a simulated running environment (excitation and load) for the UUT (Unit Under Test) to make it work in various design states, so as to obtain parameters of each state to verify the function of the UUT. To put it simply, the UUT is loaded with appropriate excitation to measure whether the output response meets the requirements. It generally refers to the functional test of PCBA.

Function test can be divided into manual control function test, sEMI-automatic control function test and full automatic control function test according to different control modes. The earliest functional tests were mainly manual and semi-automatic. For the function test of some simple boards under test, we sometimes adopt manual or semi-automatic test schemes to simplify the design and reduce the production cost. With the development of science and technology, in order to save production costs, most of the functional tests are fully automated. Another more common classification is based on the type of controller for functional testing. In the function test, we usually use MCU control mode, embedded CPU control mode, PC control mode, PLC control mode, etc.

Function test can be divided into manual control function test, semi-automatic control function test and full automatic control function test according to different control modes. The earliest functional tests were mainly manual and semi-automatic. For the function test of some simple boards under test, we sometimes adopt manual or semi-automatic test schemes to simplify the design and reduce the production cost. With the development of science and technology, in order to save production costs, most of the functional tests are fully automated. Another more common classification is based on the type of controller for functional testing.

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱