Experience sharing: PCBA inspection standard and applICation

PCBA processing supply chain is extremely long. From the operation links of component purchase, circuit board production, patch processing, plug-in, program burning, PCBA testing and packaging logistics, the quality inspection standard has always been a problem for PCBA manufacturers.

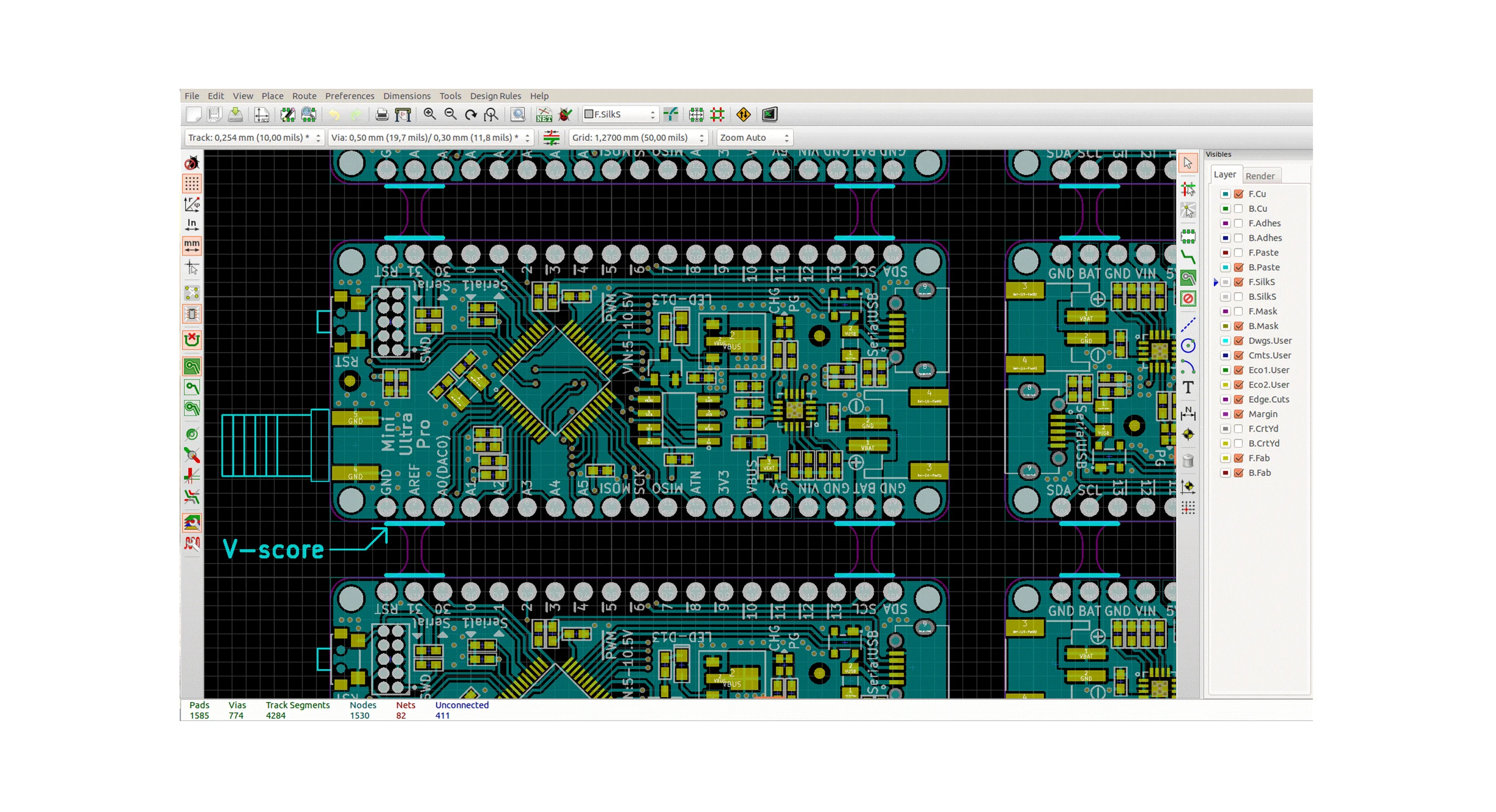

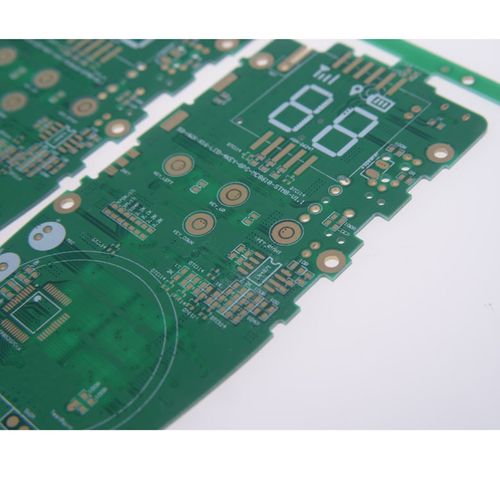

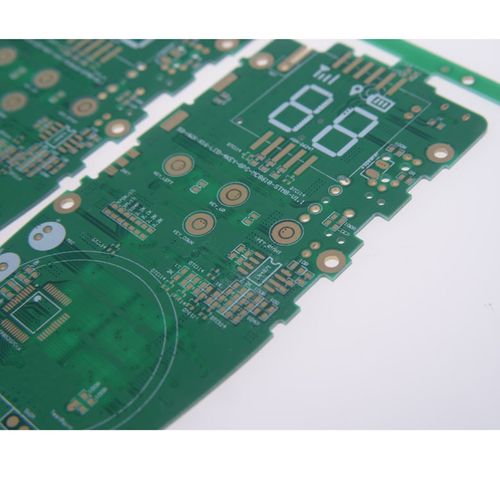

PCBA processing supply chain is extremely long. From the operation links of component purchase, circuit board production, patch processing, plug-in, program burning, PCBA testing and packaging logistics, the quality inspection standard has always been a problem for PCBA manufacturers. The IPC Electronic Acceptance Standard IPC-A-610E is known to everyone in the industry. In this manual, there are detaiLED chapters on the standards of PCBA before delivery, but for ordinary factories, it is difficult to follow them one by one, because the implementation of too large and comprehensive, detailed and complex standards will generate huge labor costs, which is also a challenge to production efficiency.

In view of this, there are many PCBA inspection standards, and we only need to carefully grasp a few of the main links to achieve quality control on the basis of ensuring efficient production and operation.

1. ICT or functional test pass criteria

The ultimate goal of PCBA inspection is that each PCBA board passes the inspection before leaving the factory. The most common one is ICT circuit inspection. As long as a very SIMple ICT test rack is made, the PCBA board can be 100% inspected. The PCBA board passing the ICT test is regarded as a part of the finished product at 90% probability.

2. Appearance standard

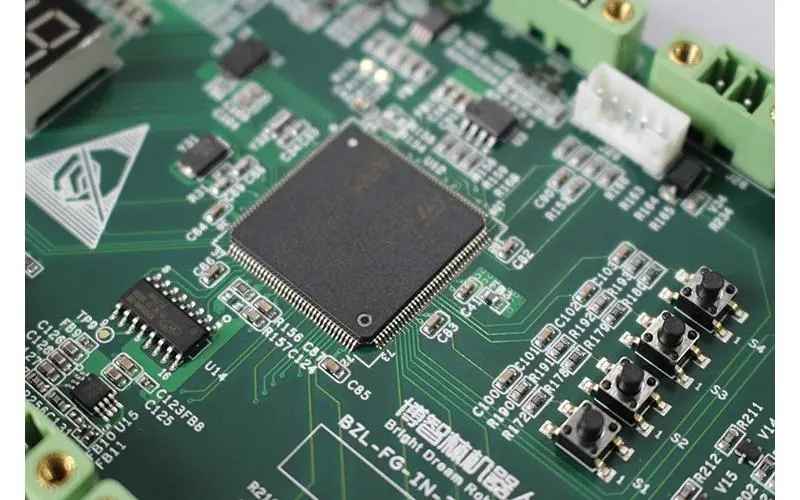

Each PCBA processing plant has an OQA delivery inspection post to visually inspect the PCBA boards before delivery (partially assist some professional instruments) to ensure that there are no obvious reliability problems, such as insufficient tin thickness, partial damage to components, etc.

3. Aging standard

In order to ensure the strict inspection standard of PCBA board, it is necessary to conduct spot check and aging test on PCBA board. Generally speaking, it is frequent power on and power off or long-time power on operation (based on the burning procedure of PCBA board). In addition, professional instruments can be used to detect electromagnetic compatibility, input and output signal stability of power supply/voltage, etc. This test takes a lot of time and can only be partially tested. Of course, we also need to provide sufficient cooperation at the customer's request.

The application of PCBA inspection standards in IPC is an important reference for our quality posts. In many cases, the standards are far below the requirements of customers. In the actual production, the process personnel of PCBA processing plant should adjust measures to the situation, give full play to their experience, and use flexible and strict standards to ensure the straight rate of PCBA boards.

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱