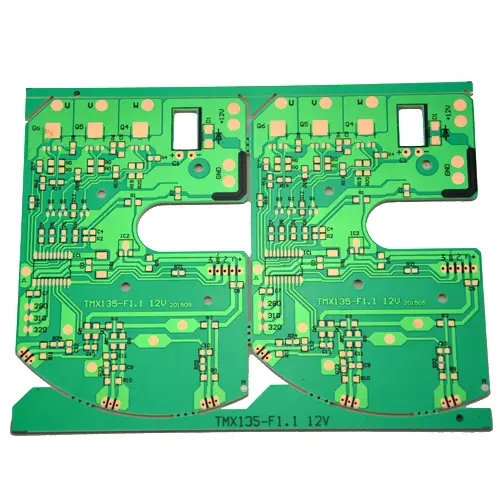

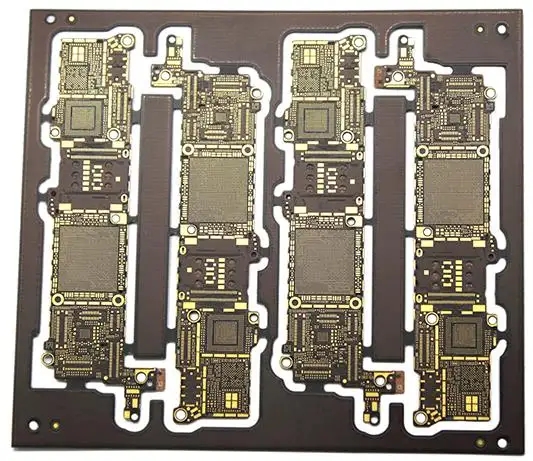

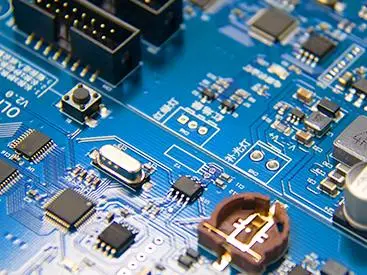

Auxiliary materials for PCBA circuit board explanation are very important

With the continuous progress of science and technology, human exploration of the unknown world has gradually deepened. All kinds of advanced equipment, along with the human desire for the unknown, have opened one mystery after another for us. But the only thing that remains unchanged is that these devICes must use PCBA circuit boards.

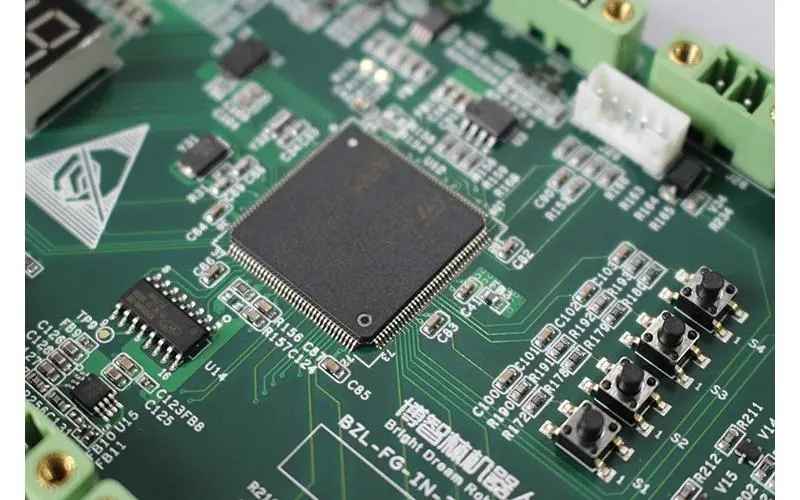

So when it coMES to PCB, we can't forget the important role of auxiliary materials. At present, the most commonly used tin lead solder and lead-free solder. The most famous is 63Sn-37Pb eutectic tin lead solder, which is the most important electronic welding material in the past century.

As tin has good oxidation resistance at room temperature, it is a low melting point metal with soft texture and good ductility. Lead is not only a soft metal with stable chEMIcal properties, oxidation resistance and corrosion resistance, but also has good formability, castability and easy processing. Lead and tin have good mutual solubility. Adding different proportions of lead in tin can form high, medium, and low temperature solders. Especially 63Sn-37Pb eutectic solder has excellent conductivity, chemical stability, mechanical properties and processability, low melting point and high solder joint strength, and is an ideal electronic welding material. Therefore, tin can be combined with lead, silver, bismuth, indium and other metal elements to form high, medium and low temperature solders for various purposes.

Basic physical and chemical properties of tin

Tin is a silvery white lustrous metal with good oxidation resistance at room temperature. It can still maintain its luster when exposed to air: the density is 7.298 g/cm2 (15), the melting point is 232, it is a low melting point metal, soft in texture and good in ductility.

1. Phase transition of tin

The phase transition point of tin is 13.2. White boron tin above the temperature of phase transition point; When the temperature is lower than the phase transition point, it starts to become powder. When the phase transition occurs, the volume will increase by about 26%. The low temperature tin phase transformation will make the solder brittle and the strength will almost disappear. The phase transformation speed is the fastest near - 40. When the temperature is lower than - 50, the metal tin turns into powder gray tin. Therefore, pure tin cannot be used for electronic assembly.

2. Chemical Properties of Tin

(1) Tin has good corrosion resistance in the atmOSPhere, is not easy to lose luster, and is not affected by water, oxygen, carbon dioxide.

(2) Tin can resist the corrosion of organic acids and has high corrosion resistance to neutral substances.

(3) Tin is an amphoteric metal, which can react with strong acids and bases, but cannot resist chlorine, iodine, caustic soda and alkali.

Corrosion. Therefore, for the assembly plates used in acid, alkaline and salt spray environments, three anti coating is required to protect the solder joints.

There are both advantages and disadvantages, which are two sides of things. For PCBA manufacturing industry, how to select appropriate tin lead solder or even lead-free solder according to different products must be considered in quality control.

It is important for PCB manufacturers, PCB designers and PCBA manufacturers to explain the auxiliary materials for PCBA PCB editors.

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱