How to judge the processing quality of SMT chip

With the development trend of electronIC products to be light, SMAll and portable, the electronIC components used in SMT processing are also becoming smaller and smaller. The resistance and capacitance components of 0402 have been largely replaced by the 0201 size. How to ensure the quality of solder joints has become an important topic of high-precision placement. As a bridge of welding, the quality and reliability of solder joints determine the quality of electronic products. That is to say, in the PCBA processing process, the quality of SMT is finally expressed as the quality of solder joints. A good solder joint should have no mechanical and electrical failure during the service life of the equipment.

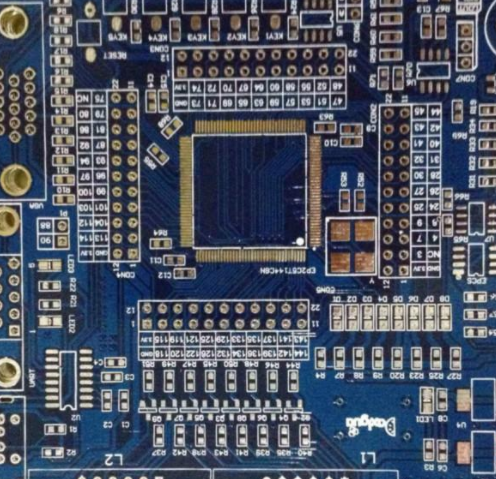

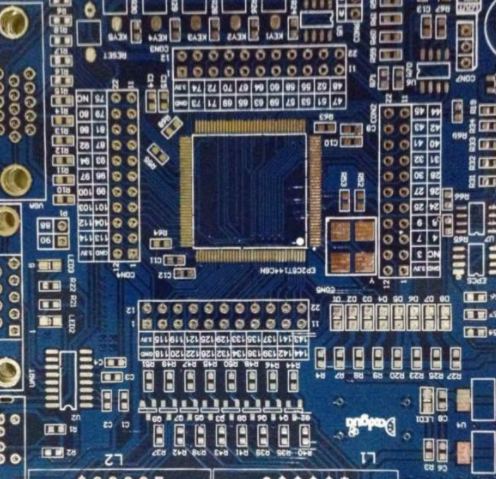

Its appearance is as follows:

1. Complete, smooth and bright surface; 2. The proper amount of solder and solder completely cover the welding position of the pad and lead, and the component height is moderate; 3. Good wettability; The edge of the welding point shall be thin, and the wetting angle between the solder and the pad surface shall be less than 300, and the maximum shall not exceed 600. The processing quality of SMT patch can be judged by visual inspection: 1. Whether there are missing components; 2. Whether the components are pasted incorrectly; 3. Whether there is short circuit; 4. Whether there is faulty welding; The first three are good for inspection. The causes of faulty soldering are relatively complex and troublesome. Next, I will introduce them to you.

1、 Judgment of faulty welding

1. Use special equipment for online tester for inspection. 2. Visual or AOI inspection. When it is found that there is too little solder at the solder joint and the solder is not well soaked, or there is a broken seam in the middle of the solder joint, or the solder surface is convex spherical, or the solder and SMD are not compatible, attention should be paid to it. Even minor phenomena can cause hidden dangers, and it should be immediately judged whether there is a problem of batch solder failure. 3. The judgment method is to check whether there are problems with solder joints at the same position on many PCBs. For example, the problem is only on individual PCBs, which may be caused by solder paste scraping, pin deformation, etc. For example, there are problems at the same position on many PCBs, which may be caused by poor components or problems with pads.

2、 Causes and Solutions of False Welding

1. The pad design is defective. The existence of through-hole in the pad is a major defect in PCB design. If it is not enough, do not use it. The through-hole will cause solder loss and lead to insufficient solder; The pad spacing and area also need standard matching, otherwise the design should be corrected as soon as possible.

2. PCB board is oxidized, that is, the bonding pad is black and does not light up. In case of oxidation, the oxide layer can be removed with an eraser to make it shine again. PCB board is affected with moisture, if suspected, it can be dried in the drying oven. PCB board is polluted by oil stain, sweat stain, etc., and then it should be cleaned with absolute ethanol.

3. For PCB printed with solder paste, the solder paste is scraped and rubbed, which reduces the amount of solder paste on the related pad and makes the solder insufficient. It shall be supplemented in time. The filling method can be used with a dispenser or a bamboo stick.

4. SMD (surface mounted components) has poor quality, expired, oxidized and deformed, resulting in faulty soldering. This is a common reason. When buying components, be sure to check whether there is oxidation, and use them in time after purchase. SIMilarly, oxidized solder paste cannot be used. The above is about how to judge the quality of SMT processing. If you have PCB products that need proofing, SMT chip processing, and PCBA OEM, please contact Electronics.

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱