SMD LED Beads Procurement and Quality Control

SMT SMD LED lamp beads are light-EMItting diodes They are decorative lighting products, usually used in commercial and home lighting industries They not only have lighting effects, but also because their light is relatively soft, they are used for interior decoration To a certain extent, it can also regulate people's emotions and relieve people's pressure As the types and types of surface mounted LED bulbs are very diverse in the SMT MARKet, attention should be paid to the details in the procurement process

1. LED lamp bead brightness

LED beads of different colors have different luminous intensities. The commonly used tissues are mcd and lm, that is, millICandela. The higher the value, the greater the luminous intensity, that is, the brighter. This is an important quota for selecting LED lights. The higher the brightness requirements, the more expensive the lamps are, because the high brightness LED chips are more expensive.

2. Color of LED

Many SMAll packaging plants do not have spectrometers and color separators, so it is difficult to guarantee the quality. The color consistency of LED without color separation is poor, of course, the price difference is relatively large.

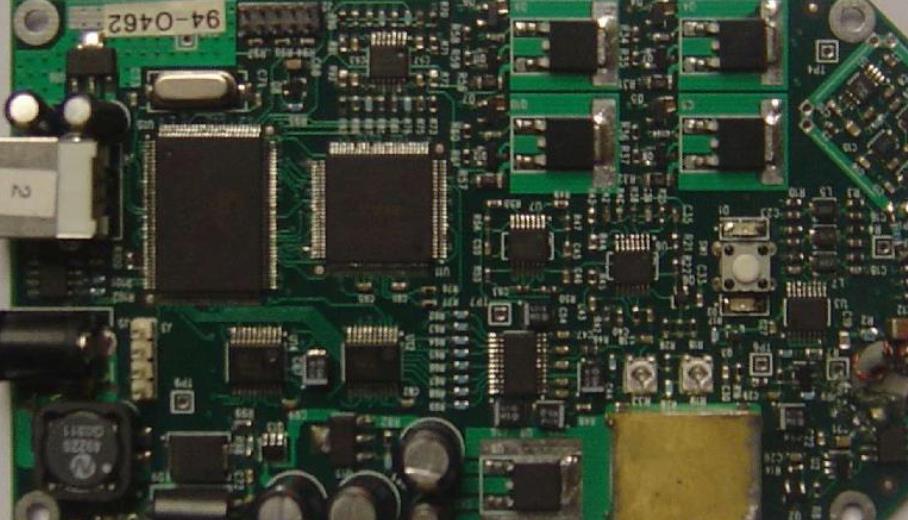

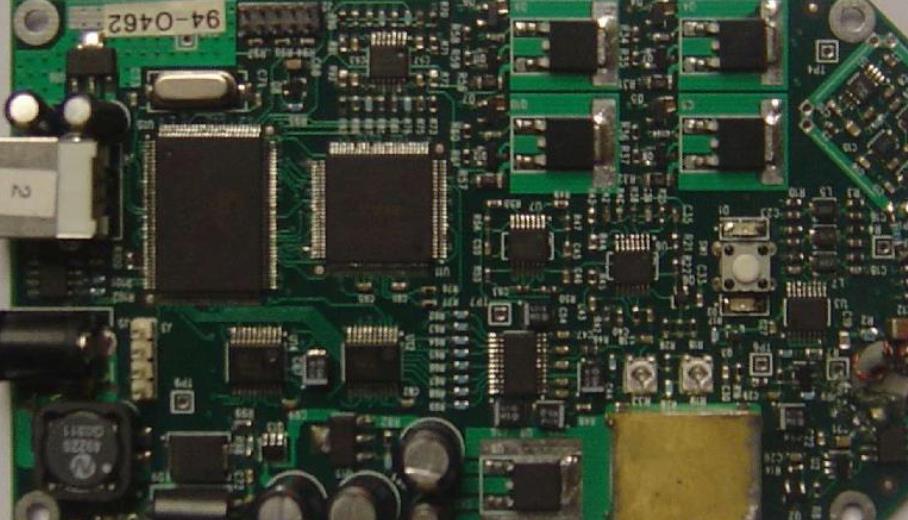

Circuit board

3. LED chip

The origin of the chip determines both the price and the quality of the lamp. Customers can usually determine the quality of LED lights by knowing the LED chip suppliers used in LED lights, because the biggest factor determining LED prices is the chip. This is one of the effective ways for experienced buyers to evaluate suppliers.

4. LED package

The packaging of LED lamp beads is divided into resin packaging and silicon resin packaging. The price of resin packaging is cheaper, because the heat dissipation efficiency is slightly poor, and the others are the same. Silicone packaging has good heat dissipation performance, and the price is slightly higher than that of resin packaging.

5. Service life

Although the service life of LED is 80000 to 100000 hours, because LED is a constant current element, the constant current effect of LED lamps produced by different manufacturers is different, and the service life is also different.

6. Color temperature

Please pay special attention to the color temperature lower than 3300K when purchasing. Light red gives a warm feeling; There is a stable atmOSPhere and a warm feeling. It is often referred to as the warm color temperature. The color temperature is between 3000-6000K. Under this color tone, people have no obvious visual psychological effect and a fresh feeling; This is called the "neutral" color temperature. The color temperature is above 6000K, and the light color is blue, giving a cool feeling. It is usually called cold color temperature.

SMT quality control

1. Data inspection

The data was inspected as IQC. Data inspection is a link to ensure the production quality, and is the basis for smooth SMT chip processing. Next, we will introduce you to the key points of inspection in detail.

1. Incoming inspection

Check whether the specification, production, model, withstand voltage, appearance and size of electronIC components and other data are consistent with the BOM provided by the customer to ensure that the data meet customer requirements. And chip inspection. The size, spacing, package and pin of the chip shall be subject to QC test.

2. Top tank inspection

Tin plating inspection shall be carried out for IC pins and components to check whether they are oxidized and the tin corrosion of the data.

3. PCB board inspection

The quality of PCB board determines the quality of finished PCB, otherwise there will be false soldering, false soldering and floating height. In this case, it is necessary to check whether the PCB board is deformed, flying wire, scratch, circuit damage, and whether the board surface is flat.

4. PCB board tin eating inspection

The wettability affects the tin corrosion rate of PCB, and the poor tin corrosion rate will lead to insufficient solder joints.

5. Through hole inspection

The size of the through-hole position is determined according to the size of the component. If it is too small or too large, the part cannot be inserted or dropped.

2. Solder Paste Inspection

Solder paste source: we use international brand Senju solder paste, which is provided by professional suppliers. Solder pastes are used according to the "first in, first out" standard, that is, they are purchased first and used first. The storage temperature of solder paste is usually between 0 ° C and 10 ° C, plus or minus 1 ° C. Solder paste needs to be thawed before use. Generally, it takes about 4 hours at room temperature. It needs to be marked for use and the rest needs to be recycled. However, the second recycling needs to be recycled to the supplier for treatment to avoid environmental pollution. The solder paste needs to be stirred with an automatic mixer for 5 minutes before use to prevent bubbles from entering the welding process.

3. Wire MESh and scraper control

The size of wire mesh is generally 37cm × 47cm, with tension of 50-60MP. Generally, tension testers are used for tension testing. The storage temperature of the steel mesh should be better controlled at 25 ℃, and the edge of the steel mesh is rubber. If the temperature is too high, it will become brittle and damage the steel mesh. The scraper is operated at a 45 degree angle, and the ordinary wire mesh scraper is scrapped after 20,000 times of use. As the thickness of the steel mesh will become smaller, the tension of the steel mesh will be affected, and the tin scraping will be incomplete.

Fourth, the adjustment of the placement machine and the first QC

Adjust the coordinates of the automatic placement machine according to the coordinate files such as BOM, template and ECN files provided by the customer to ensure accurate measurement and high placement accuracy. This is the first QC inspection of placement. The quality inspector shall check whether there is missing pasting, flash, placement direction, placement accuracy, etc., and batch production can be carried out after confirmation.

5. Reflow welding control and secondary QC

The temperature setting of reflow soldering requires different parameter settings according to the PCB data, such as cardboard, 2-layer board, 4-layer board or ceramic board. At the same time, PCB passes through the furnace to control the gap, direction and position of the board. At this time, the first reflow soldering is subject to the second QC inspection and test to ensure that the tin is not melted, the components are yellow, and there is no faulty soldering. After confirmation, batch production is carried out. This test requires an AOI test to check whether the monument is erected.

6. 3rd QC test

This inspection is the QA inspection of the Quality Department The Quality Department needs to package and ship PCB products after they are qualified

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱