Prevent damage and collision of SMT components

With the development of electronIC product technology, circuits are becoming more and more intensive, the number of components on a single board is increasing, and the risk of component damage is also increasing In this paper, how to avoid damage to parts in surface mount process is described in detail

Operational issues leading to collisions

Process damage Impact fracture, stress damage

1 Improper casing setting

When bending stress is applied to placement or testing, supports in adjacent areas will be destroyed.

The damage of the resistor is characterized by breakage or electrode peeling, and the capacitor is in an inclined crack mode. If it is the first process part, the tombstone of broken parts may appear after reflow.

2. Stress damage

Poor plate feeding results in deformation or manual bending of the clamping plate (clamping plate); Poor suction nozzle and improper height setting may damage components.

The typical feature of damage is frontal fracture, which usually separates after passing through the furnace; If the side is damaged, the chamfered slope is mostly cut off. In this case, the location of the collision point can be clearly distinguished.

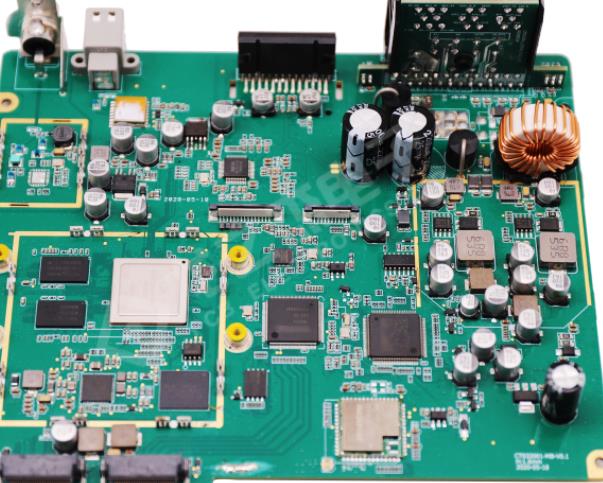

Circuit board

Operational issues leading to collisions 2.

Damage after impact fracture of SMT process,

Stress damage, delamination (thermal shock)

1 Impact fracture

In general, it is difficult to determine the collision point in the lateral collision, because the pad is usually stripped (resistance) or the electrode of the part is broken (capacitance); Although the impact point is easier to identify in the longitudinal impact part, and the gasket is usually not damaged, the part can see obvious defects. horn

2 Stress damage

Damage caused by pressure and bending caused by sheet edge folding, test fixture, trolley placement, etc. This type of damage usually occurs in the form of inclined cracks.

3-layer stripping

SMT welding is caused by improper maintenance Typical features are black flux burning near the part, discoloration of rough surface, layer peening (capacity), character surface peeling, etc

How to start analyzing damaged parts

1 Analysis points according to impact

The existence of the impact point is not an absolute analysis and judgment factor, but usually the location, direction and damage degree of the impact point will provide a lot of analysis information.

a. The linear impact force usually damages the PCB, and obvious damage defects can be seen on the components.

b. The parallel impact force will directly cause part damage due to fracture and missing angle. However, due to the SMAll torque direction, it will not cause serious damage to the gasket in most cases.

2 According to crack shape

a. Delamination crack: most of the delamination is caused by thermal shock, but part of the reason is the poor manufacturing technology of SMT components, because interlayer bonding and baking process defects lead to delamination after reflow welding.

b. Inclined crack: because the bending stress forms a fulcrum at the lower part of the part, the fixed solder joint produces inclined surface fracture at the electrode end, especially for large components perpendicular to the stress direction.

c. Radial cracks: radial cracks usually have the following impact points, which are mainly caused by point pressure, such as casing, suction nozzle, test fixture, etc.

D. Complete rupture: Complete rupture is the most serious failure mode, usually accompanied by PCB damage. It is usually caused by lateral impact or capacitor crack, resulting in equipment burning.

3 According to the displacement of parts

When the part has longitudinal cracks or reflow heating but is not cracked, it is likely to see only cracks but not separation, which will lead to inspection problems. Due to the tension of solder melting, the cracks generated before reflow will be pulLED. Even during the reflow process, there will be a tombstone on the broken part. Most of the reasons are component damage in the first process, bending stress or improper ejector pin setting in the second process. Of course, cracks caused by cutting and packaging during component manufacturing may also be cracked due to the heat after reflow welding.

The root causes of problems in production and

Solutions

1 Warehouse storage

Problem 1: The incoming materials are poor, and the incoming packaging pipeline is unreasonable.

Solution: ask the supplier to improve the packaging method.

Problem 2: The temperature and humidity of the warehouse do not meet the standards.

Solution: The warehouse manager shall regularly check whether the thermometer and hygrometer are within the specification range.

Problem 3: The storage and packaging methods are unreasonable.

Solution: strict and professional storage and stacking methods to prevent deformation, creep and damage of parts by packaging methods.

2 Material preparation room

Problem 1: In the process of transferring materials from the warehouse, parts may be damaged due to falling and impact.

Solution: Add protective railings on the data shelf.

Problem 2: When the packaging method is changed, the parts are damaged due to incorrect operation method.

Solution: Standardize the operation.

Problem 3: The vacuum packaging of humidity sensitive parts is damaged, resulting in air leakage, etc.

Solution: online after baking or vacuum packaging after baking.

3SMT production line picking

Problem 1: In the process of transferring materials from the preparation room, parts may be damaged, such as falling and impact.

Solution: add protective railings on the data shelf.

Problem 2: Parts are damaged in the process of receiving data or cutting data.

Solution: Use the correct methods and tools.

4 Entering the Board of Directors

Problem: PCB board is bent and deformed when entering the tool magazine non parallel.

Solution: When installing the board, install the board in parallel to avoid collision between PCB and tool magazine.

5KG printing, CP placement

Problem: The top pin in the machine is set incorrectly, causing the back weld to be knocked out.

Solution:

1. The ejector pin diagram created by the operator can only be used after being confirmed by the operator.

2. Before opening the circuit, IPQA shall check whether the top pin is consistent with the top pin diagram

6 CP and QP components

Problem 1: The height setting in the part data is less than the height of the part body, and the part is crushed when it is placed.

Solution: The height of the part data should be greater than or equal to the height of the part body.

Problem 2: The jack pin height is abnormal.

Solution: Unify the height of the top pin. Measurement is required after adjustment.

7 Backflow

Problem: When the loader in front of AOI is full, the rail emergency switch is pressed or the rail sensor fails, the front plate will not flow downward after the reflux furnace is discharged, but the plate passing through the reflux furnace continues to flow downward, causing the back plate to hit the front plate.

Solution:

1. Improve AOI detection speed;

2. The SMT production line arranges personnel near the station to pay attention to the buzzer alarm and ensure that the plate is taken out before collision

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱