Introduction to rigid and flexible industrial PCB types

Industrial PCB is based on rigid and flexible types:

In addition to layers, PCB can also be divided into different parts according to the stiffness. According to the stiffness, PCB can be divided into 3 types.

rigid PCB:

Rigid PCB is a rigid PCB in essence.

The base plates of these printed circuit boards are not flexible. rigid PCBs are widely used in industrial applICations.

Due to its solid base material, it is durable and easy to maintain.

Rigid PCBs usually handle very complex designs. It is easy to realize and organize signal path on rigid PCB.

The compact size of rigid PCB ensures that various complex designs can be carried out around it in one application.

Like rigid PCB, all components are fixed with flux.

The whole process is completed in such a way that even if you use them in a harsh application environment, all components on the PCB will not move.

flexible printed circuit board:

A Flexible circuit board is a circuit board SIMilar to a rigid circuit board, and its necessary components are placed on a flexible substrate instead of a rigid substrate.

Circuit board

The manufacturing pipe of the plate can make it bend into any required shape during application.

flexible PCB is inherently flexible

You can fold it easily. The base material of flex PCB is flexible.

This type of PCB also has single-layer, double-layer and multi-layer formats.

Because this type of printed circuit board is light and flexible, it is widely used in industrial applications.

There are different types of flexible circuit boards according to the number of layers and configurations.

This type of PCB also has single layer, double layer and multi-layer forms.

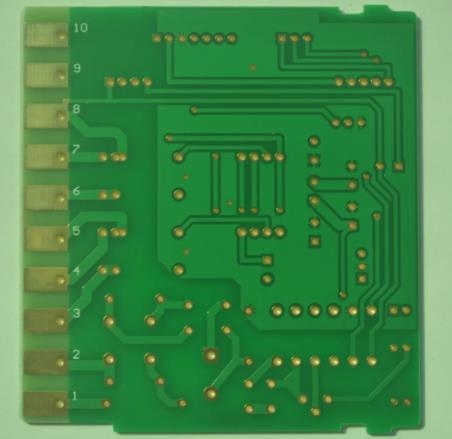

Rigid and flexible combined PCB:

rigid flexible PCB is a hybrid PCB of rigid PCB and flexible PCB.

Many rigid printed circuit boards are used for rigid flexible printed circuit boards. The rigid part of the rigid flexible plate is usually used to place the connector and install the chassis.

This rigid and flexible design helps to increase the capacity of any PCB.

The biggest advantage of rigid flexible PCB design is that it does not require any compromise in device or application design. Considering the convenience of users, any type of design can be carried out.

This kind of circuit is mainly used to realize complex circuits. It is used when the circuit space is minimum but the circuit complexity is maximum.

Because of its rigidity and flexibility, it is one of the most commonly used circuits in industrial applications.

HDI Flex PCB:

The full name of HDI is HD Internet.

This type of PCB is used for devices or applications that require higher performance than general Flex PCBs.

This layout is particularly helpful for creating a perfect layout. It uses much thinner layers than conventional Flexible PCBs, which helps reduce overall size and make efficient use of energy.

Select this type of PCB to create a high-performance PCB. These types of PCBs can be used for industrial applications as needed.

high frequency PCB:

This type of PCB operates at a high frequency of 500MHz to 2GHz. This type of PCB has been used for critical frequency applications.

There are other types of PCB, such as high-speed PCB, LED PCB, RF PCB, METALCORE PCB, thick copper PCB, golden finger PCB, ceramic PCB, etc.

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱