Don't make mistakes in SMAll steps of PCB design

PCB manufacturing, PCB design and PCBA processing manufacturers will explain the small and medium steps of PCB design. Don't make mistakes

(1) design of circuit schematIC diagram: The design of circuit schematic diagram mainly refers to the Advanced Schematic of PROTEL099 to draw a circuit schematic diagram. In this process, we should make full use of various schematic drawing tools and editing functions provided by PROTEL99 to achieve our goal, that is, to get a correct and beautiful schematic circuit.

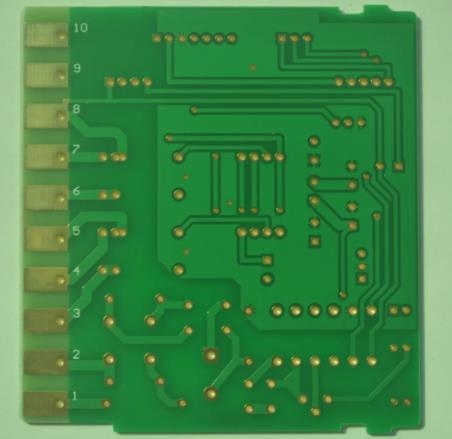

(2) Generate network table: network table is a bridge between circuit schematIC design (SCH) and Printed Circuit Board Design (PCB), and it is the soul of circuit board automation. Network table can be obtained from circuit schematic diagram or printed circuit board.

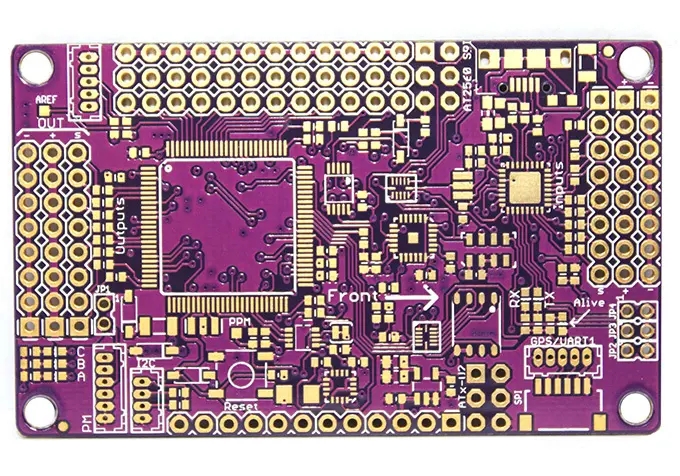

(3) PCB design: PCB design is mainly aimed at another important part of PROTEL99 PCB. In this process, we use the powerful functions provided by PROTEL99 to achieve the layout design of PCB and complete difficult work.

However, in practice, the detaiLED steps are mainly as follows:

1、 Preliminary work of circuit board design 1. Use schematic design tools to draw schematic diagrams and generate corresponding network tables. Of course, in some special cases, such as the circuit board is relatively SIMple and there is a network table, you can also enter the PCB design system directly without schematic design. In the PCB design system, you can directly take parts for packaging and manually generate the network table. 2. Manually change the network table to define pads that are not on the schematic diagrams such as fixed pins of some components to the network connected to it. Pads that are not physically connected can be defined to the ground or protected ground. Change the device pin naMES in some schematic diagrams and PCB packaging library that are inconsistent with the pin names to be consistent with those in PCB packaging library, especially diode and triode.

2、 It is recommended to put the components you have drawn into a PCB library special design file you have created.

3、 Set the PCB design environment and draw the stencil frame of the printed circuit, including the middle hollowing. 1. The first step after entering the PCB system is to set the PCB design environment, including setting the grid size and type, cursor type, plate layer parameters, wiring parameters, etc. Most parameters can use the system default values, and these parameters, after being set, conform to personal habits and do not need to be modified in the future. 2. Planning the circuit board is mainly to determine the border of the circuit board, including the size of the circuit board, etc. Place a pad of appropriate size where the fixing hole needs to be placed. For 3mm screws, pads with 6.5~8mm outer diameter and 3.2~3.5mm inner diameter can be used. For standard boards, they can be transferred from other boards or PCWizard. Note - Before drawing the circuit board ground frame, be sure to set the current layer as the KeepOut layer, that is, prohibit the routing layer.

4、 After opening all the PCB library files to be used, it is a very important step to call in the network table file and modify the part packaging. The network table is the soul of PCB automatic wiring, and is also the interface between schematic design and impression circuit board design. Only after the network table is loaded can the circuit board be wired. In the process of schematic design, ERC inspection will not involve the encapsulation of parts. Therefore, the packaging of parts may be forgotten during schematic design, and the packaging of parts can be modified or supplemented according to the design situation when introducing network tables. Of course, you can manually generate the network table directly in the PCB, and specify part packaging.

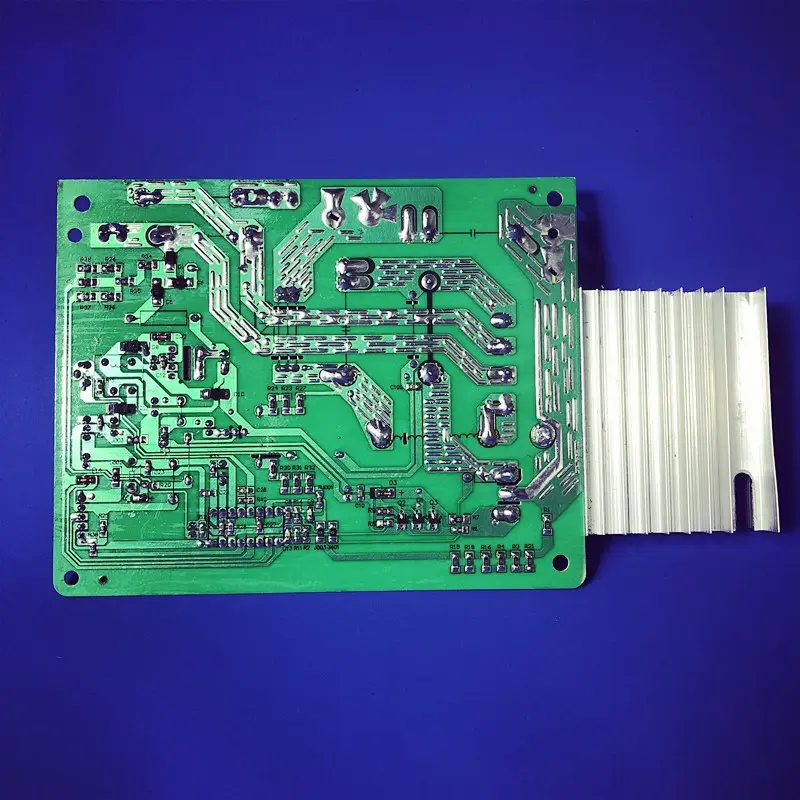

5、 The location of part package, also known as part layout Protel99, can be arranged automatically or manually. For automatic layout, run "AutoPlace" under "Tools". With this command, you need to be patient enough. The key of routing is layout, and most designers adopt the form of manual layout. Select a component with the mouse, press and hold the left mouse button, drag the component to the destination, and release the left button to fix the component. Protel99 has added some new skills in layout. New interactive layout options include automatic selection and automatic alignment. Using the automatic selection method, you can quickly collect components with similar packages, then rotate, expand and organize them into groups, and then move them to the desired position on the board. When the simple layout is completed, use auto alignment to neatly expand or shrink a group of encapsulated similar components. Tip - Use ShiftX or Y and CtrlX or Y to expand and shrink the X, Y direction of the selected component during automatic selection. Attention - The layout of parts shall be comprehensively considered from the aspects of heat dissipation of mechanical structure, electromagnetic interference, convenience of future wiring, etc. First, arrange the devices related to mechanical dimensions, and lock these devices, then the large occupying devices and the core components of the circuit, and then the small peripheral components.

6、 Make appropriate adjustment according to the situation, and then lock all components. If the space on the board allows, some wiring areas similar to the experimental board can be placed on the board. For large plates, additional fixing screw holes shall be added in the middle. Fixed screw holes shall also be added on the side of stressed components such as heavy components or large connectors on the board. If necessary, some test pads can be placed at appropriate locations, preferably in the schematic diagram. Enlarge the vias of pads that are too small, and define the network of all pads with fixed screw holes to the ground or protective ground. After placing it, use the VIEW3D function to check the actual effect and save it.

7、 Routing Rules Setting Routing rules is to set various specifications for routing (such as the use layer, line width of each group, via spacing, topology structure of routing, and other rules, which can be exported from other boards through the Menu of Design Rules, and then imported into this board). This step does not need to be set every time. It can be set once according to personal habits. PCB manufacturing, PCB design and PCBA processing manufacturers will explain to you the small and medium steps of PCB design. Don't make mistakes.

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱