Robot PCB controller and Its design and Development

The design and development of mobile phone PCB controller is a research hotspot of mICro - probe robot The practical experience of developing modern robot control system shows that, on the basis of existing theories and PCB technology, the technical conditions for studying highly intelligent autonomous robots are not yet mature; For field robots, due to the reliability and delay of communication, it is impossible to guarantee the diversity and complexity of the environment, which will lead to limited information access. Pure manual teleoperation leads to reduced control reliability and increased complexity Therefore, this is a more realistic and feasible method for the research and design of monitoring mobile robots in the unique environment of specific tasks

System components

The purpose of the field exploration robot determines that the robot must be SIMple, reliable, replaceable and easy to upgrade to make it full of vitality.

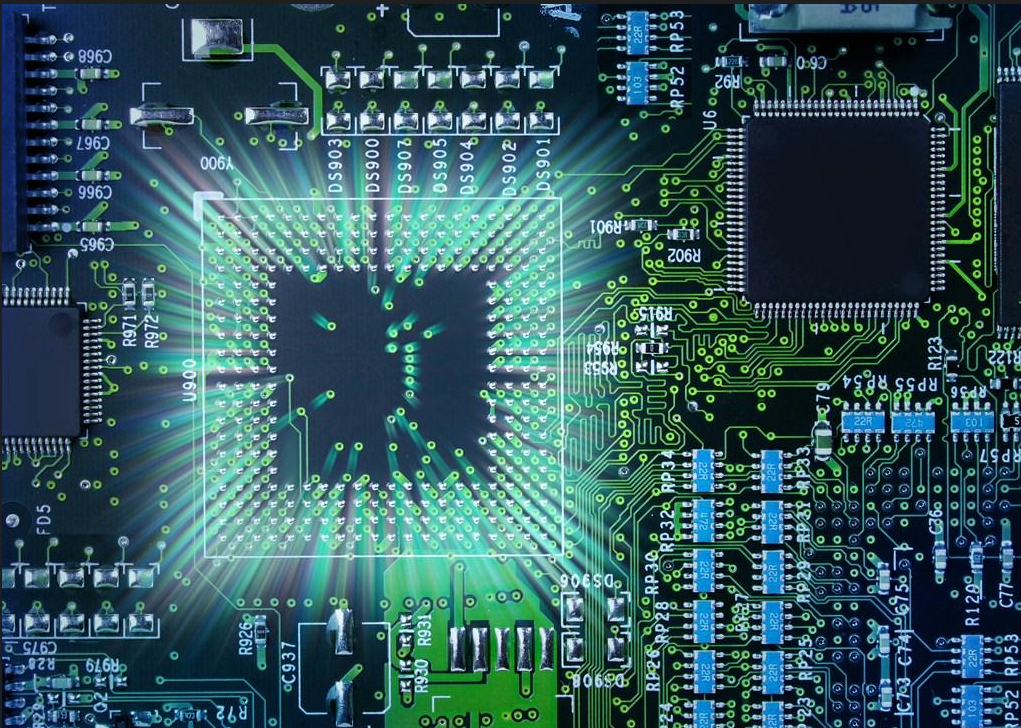

Circuit board

PCB hardware composition

The robot adopts a track leg compound moving mechanism. The compound motion mechanism is mainly used in the application of mobile robots in the unstructured environment, in order to improve their passing ability in the unstructured environment. This project is calLED "goat" robot,

The core main controller adopts PC104 provided by Swiss Digital Logic Company. As a new and powerful bus form and special control equipment, PC104 adopts a standard building block hardware structure, which is easy to expand functions and ports; It has strong computing power, which makes the robot have the characteristics of fast processing speed and strong ability; Its heat resistance, cold resistance, moisture resistance and seismic resistance are suitable for harsh outdoor conditions. The console system uses the German WOGO industrial MODBUS adapter similar to PLC as the control core. The communication between the upper computer and the lower computer follows the MODBUS protocol and is realized through the wireless data transmission station. The modular software design of the WOGO industrial MODBUS adapter is stable and reliable, which is very suitable for applications such as data acquisition and data display of the robot console.

The robot motion control system is the core of robot controlling each axis motor to realize remote operation. The system adopts PMAC2 motion control card with PC104 interface provided by Deltaau Company, which can control four motors at the same time to realize four axis linkage. It can realize the following functions: executing motion program, executing servo loop update, motor commutation update, software and hardware security resource management, communicating with host, task priority organization, etc. This is an extremely powerful motion control card. The wireless data communication system adopts American MDS wireless data transmission station, which has a standard RS232 communication port, uses PCB wireless spread spectrum technology, and uses 220M frequency band. It is mainly used for remote PCB wireless point-to-point or multi-point wireless data communication. The transmission rate can reach 15.2Kbps, and the indoor communication distance can reach 300 meters using a 2db antenna.

The robot observation system adopts SURF series wireless image transmitting/receiving system, which consists of two monitors and a wireless image transmitting/receiving system. The two CAMeras are respectively installed at the front end and upper end of the robot body. By returning remote images, remote monitoring can be realized in an unstructured environment.

. Implementation

Now, the robot can realize the functions of going up and down standard pedestrian stairs, crossing ditches (less than 30cm), automatic reset when turning, going up and down elevated platforms (less than 30cm in height) and walking in the sand. Man machine has better coordination and control. As shown in Figure 2 above, you can see some corresponding behavioral abilities.

In short

The supervisory PCB controller has good adaptability in the field mobile robot control Operators can observe task execution through PCB monitor and status echo, which greatly reduces the working pressure and skill requirements of operators; The robot has certain autonomy. Under the monitoring level model, the robot's autonomy can be further developed and the system can be easily upgraded It can also be used as a research platform for robot autonomous control; For robot safety problems caused by the following reasons, there is a relatively safe and feasible solution: PCB signal delay, uncertainty in unstructured environment, mechanical and electronic failures, etc In the subsequent research, various sensors will be further assembled to improve the autonomy of the robot, add the ability of online learning and updating the knowledge base of the robot, and improve the operator interface to make it more humanized, etc, Make the robot a development and research platform, It can also become a practical, reliable and usable product

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High Frequency Circuit Board and SMT chip are waiting for your presence again.

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱