OSP PCB Process Operation Method

Formulate the production operation procedure for OSP PCB online to reduce the phenomenon of empty soldering, cold soldering, poor tin eating and even PCBA scrapping caused by this PCB in the manufacturing process.

1.0 Purpose:

Formulate the production operation procedure for OSP PCB online to reduce the phenomenon of empty soldering, cold soldering, poor tin eating and even PCBA scrapping caused by this PCB in the manufacturing process.

2.0 Scope:

All OSP PCB products produced by the company

3.0 Units responsible for operation:

3.1 Purchase Department (PUR):

Responsible for PCB procurement and PCB rework arrangement

3.2 Product Engineering Department (PED):

Formulate OSP PCB operation procedure and PCB manufacturer's approval

Formulate production flow chart of OSP PCB products

3.3 Manufacturing Department (MFD):

Carry out production operations according to the OSP PCB process operation method

3.4 Operation Department (OP):

Be responsible for scheduling control

3.5 Incoming Quality Control Department (IQC)

Responsible for PCB incoming inspection and solderability judgment

3.6 Storage Department (SM)

Be responsible for warehouse management and inventory PCB Date code check

4.0 Definitions:

nothing

5.0 Operation content:

5.1 PC part

5.1.1 As OSP PCB production must complete all welding production actions within 24Hrs after the PCB is unpacked, the production manager is requested to adjust the number of work orders according to the time required in the following table when scheduling work orders. When the same work order cannot be completed within the time specified in the following table according to the standard working hours, please unpack the work order and go online in batches.

5.1.2 Before going online, please confirm whether the SMT&PTH material condition is Ready. If there is a shortage of material, it cannot be arranged to go online.

5.2 SMT part

5.2.1 Because OSP PCB is easy to oxidize, it is prohibited to unpack and bake PCB before it is put on line.

5.2.2 During production, if the number of work orders is too large to complete the production in two hours, please unpack the vacuum packaging of PCB in batches. It is forbidden to unpack all at once (the unpacking quantity is based on the required quantity produced per hour). When unpacking at the SMT site, if the incoming materials are attached with a humidity display card, it must be confirmed that the humidity display card meets the specifICation and the production is completed within the specified time. It is necessary to confirm whether the OSP production date of the PCB is more than 3 months. If it is more than 3 months, it is necessary to return it to the warehouse or find the Engineering Department and SQE for experiments.

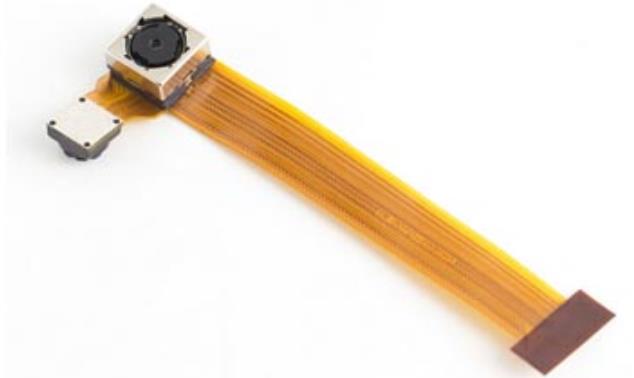

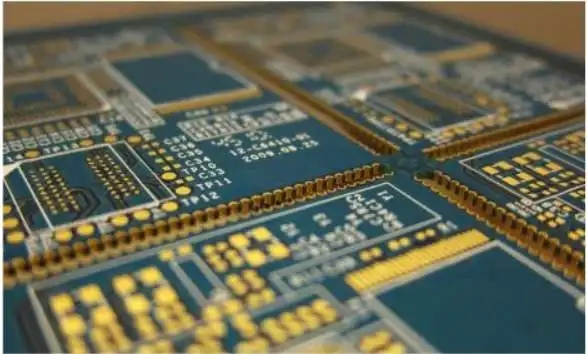

5.2.3 Before going online, check whether there is oxidation discoloration on the surface of PCB pad (as shown in Annex I). If discoloration needs to be returned to the warehouse, please purchase and send it back to the Pcb factory to rework the OSP process.

5.2.4 Before going online, ask SMT materials to confirm whether all materials are ready. If SMT cannot go online for production due to lack of materials, do not unpack the PCB.

5.2.5 Please fill in the PCB unpacking time on the Product Identification Card, so that each process section can control the production time.

5.2.6 In case of any rejection by IPQC, the production shift at the time of rejection shall deal with it immediately, and shall not place it on the shift producing the defective PCBA for treatment, so as not to delay the time limit.

5.2.7 During the design of solder paste printed steel plate, solder shall be completely covered on the solder pad as much as possible, and the coverage rate after tin melting shall at least reach more than 90% of the area of the solder pad.

5.2.8 For the PAD or through hole used for ICT/MDA test, when the solder paste is used to print the steel plate, the opening size of the steel plate is more than 50% of the area of the test PAD or through hole, and it is covered with solder paste to avoid poor contact of the probe during the subsequent test.

5.2.9 When the PCB printing solder paste is defective, it cannot be soaked or cleaned with highly volatile solvent. The solder paste can be wiped with non-woven cloth DIPped with 75% alcohol, and the SMT soldering operation on the PCB surface can be completed within 2 hours.

5.2.10 If the production needs to be carried out in the online mode due to lack of materials due to shipping demand, the steel plate still needs to print solder paste at the position of lack of materials when printing solder paste, and it is not allowed to paste the solder paste at the position of lack of materials to avoid PAD oxidation and failure to solder parts later.

5.3 IPQC

5.3.1 Due to the timeliness problem, IPQC is changed to on-line inspection.

5.4 PTH

5.4.1 PCBA cannot be baked.

5.4.2 After SMT transfer in, please produce according to the specifications in Table 1. The production time must be calculated from SMT unpacking and all welding operations must be completed within 24Hrs.

5.4.3 The tin content in empty PTH holes without parts is not required. If no special instructions are provided by the customer, the tin content in the hole with parts shall be subject to IPC standards.

5.5 PCB storage conditions&shelf life

5.5.1 The storage environment of PCB before unpacking is: temperature 20~30 ℃, relative humidity: ≤ 60%.

5.5.2 The OSP film meets the above storage conditions and is unopened vacuum packaging. The shelf life of the OSP film is 3 months. One month before the shelf life, it needs to be returned to the manufacturer for rework. After the rework is OK, it can be used for another 3 months. The PCB warranty period is 6 months, and it cannot be baked.

5.5.3 OSP PCB incoming materials shall be vacuum packed (humidity test paper is not required for non marine transportation)

5.5.4 The warehouse shall summarize the PCB Date code and send it to IQC, material control and procurement, and the material control shall notify PM&procurement to send it back to PCB factory for rework (OSP processing again) within one month before the OSP film exceeds the warranty period; Otherwise, it will be scrapped after 3 months; The reworked PCB must be put into use within 3 months. If it is not used, it will be scrapped

5.5.5 The OSP PCB is only allowed to be reworked once, and the service life can be extended for another 3 months after reworking. In this case, it must be calculated based on the date of reworking, not the PCB Date Code. The supplier must MARK the completion date of rework on the outer package as the judgment basis for incoming inspection and SMT launch. If the reworked PCB is still found oxidized or blackened after IQC re inspection, it shall be returned for processing. The reworked PCB must be put into use within 3 months. If it is not used, it will be scrapped.

5.6 Requirements for process control

5.6.1 When the production OSP PCB is opened for vacuum packaging by SMT, please record the opening time on the Product Identification Card and check whether the copper foil on the PCB surface is oxidized (as shown in Annex I). If not, please immediately notify the purchasing department to notify the PCB factory to deal with it. If not, please go online for production immediately after unpacking.

5.6.2 The OSP PCB shall not be baked during the whole manufacturing process to prevent the organic oxidation resistant film from dissolving when it is damaged at high temperature, which will lead to the oxidation of the copper foil surface and lead to poor tin eating.

5.6.3 After the vacuum packaging is unpacked, all welding operations must be completed within 24 hours, so as to avoid the phenomenon of poor tin eating caused by copper foil oxidation.

5.6.4 If the PCB is not used after unpacking, the purchaser shall notify the PCB factory to rework the OSP process and put it into storage in vacuum packaging. If it cannot be disposed, it shall be disposed of as scrap.

5.6.5 During the production of OSP PCB, please ask the production manager to assist in arranging production in a timely manner, and try to complete the production from SMT to PTH in the shortest possible time, which shall not exceed the specified time limit, otherwise the copper foil will be oxidized and lead to poor tin coating.

5.6.6 If the PCB plate is FR1, please note that the copper foil of the plate is easy to fall off (compared with FR-4) during repair welding and maintenance. The temperature of the soldering iron should be set according to the Operating Standard for Soldering Iron (D103-009002). During welding, please note that the soldering iron should not be forced to poke on the copper foil to prevent the copper foil from falling off.

5.6.7 Please wear gloves throughout the production process and do not touch the PCB copper foil surface with your hands to avoid PAD pollution and oxidation solder refusal.

5.6.8 Once all PCBs are unpacked, the production of all welding operations must be completed within 24 hours. If material problems are found in half of the production (such as wrong material, lack of material...), the production of SMT and PTH processes must be completed within 24 hours for the unpacked parts to avoid PCBA scrapping.

5.6.9 All exposed copper parts of the OSP PCB must be tinned (screw holes (including screw plum holes) are tinned by SMT steel MESh in the form of plum holes, and the degree of tinning is: 50%~65% of the screw holes are covered). To prevent copper and platinum from being oxidized when exposed to air for a long time.

5.6.10 In the case of dual PAD layout, the PAD below the chip is not allowed

5.6.11 The minimum allowable safe distance of transistors is 1.0mm. Empty PADs beyond the distance must be tinned in the form of "Tian" or all.

5.6.12 Tin is not allowed on the antenna.

5.6.13 Heat dissipation PAD shall be coated with tin in the form of "Tian" shape for more than 75% of the area.

5.6.14 The screw holes and optical points of the stack interface of the switch product are not allowed to be tinned.

5.7 PDE part

5.7.2 When developing the production flow chart of OSP PCB products, PED must fully consider the prerequisite requirement of "completing all welding operations within 24 hours of production"

5.7.2 When switching to OSP process, it is required to Review whether the product flow chart of all applications of the PCB with this material number meets the prerequisite requirement of "completing all welding operations in 24-hour production".

5.8 Silver plate

Please refer to the OSP PCB to execute the production action. However, it must be ensured that the silver plate is isolated from sulfur containing substances in the production process.

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱