What is DFM

Manufacturability - also known by all parties as concurrent or SIMultaneous engineering or design for productivity or assembly - is different from the way that R&D engineers establish their own design prototypes, The traditional PCB manufacturing method of sending it to the production department to assemble online without the advICe of the front line production workers enjoys great advantages. On the other hand, members of a manufacturability team include designers, PCB manufacturing engineers: MARKeting representatives, financial managers, R&D personnel, raw material suppliers and other plan stakeholders (including customers). Because it includes people from all sides, it will also help to accelerate the completion of the plan and avoid the delays that traditional production methods will encounter.

It mainly studies the relationship between the physical characteristics of the product itself and various parts of the manufacturing system, and applies it to product design, so as to integrate the entire manufacturing system for overall optimization, make it more standardized, so as to reduce costs, shorten production time, and improve product manufacturability and work efficiency. Its core is to participate in the whole design process from the preliminary planning of the product to the production of the product without affecting the product function, so as to make it standardized and simple, and make the design conducive to production and use. Reduce the manufacturing cost of the whole product (especially the components and processing technology). Reduce the process flow, select the process with high pass rate, standard components, and reduce the complexity and cost of molds and tools.

Process method of design for manufacturability

To introduce DFM, first of all, we should recognize its necessity, especially the leaders of production and design departments should be convinced of the necessity of DFM. Only in this way can designers consider not only the primary goal of function realization, but also the problems in production and manufacturing. That is to say, no matter how perfect and advanced the function of the product you designed is, it cannot be successfully manufactured or it will cost a lot of PCB manufacturing costs to produce, which will lead to rising product costs, sales difficulties and loss of market.

Secondly, unify the information before the design department and the production department, and establish an effective communication mechanism. In this way, designers can consider the production process while designing, so that their design is conducive to production and manufacturing.

Third, select personnel with rich production experience to participate in the design, test and evaluate the manufacturability of the design results, and assist the designers in their work. Finally, arrange reasonable time for designers and DFM engineers to go to the front line of production to understand the production process and production equipment, and understand the problems in production. In order to better and more systematically improve their design.

1. Seek and establish our company's DFM series specification documents: DFM documents shall be reasonably formulated in combination with our company's production design characteristics, process level, equipment and hardware capabilities, product characteristics, etc. In this way, the current and future production capacity of the factory must be considered when selecting the assembly technology in the design. These documents can be very simple terms, and can also be a complex and comprehensive design manual. In addition, the documents must be timely maintained according to the company's production development, so that they can more accurately meet the current design and production needs.

2. While planning the product design, establish the DFM checklist according to the company's DFM specification documents. The checklist is a tool for systematic and comprehensive analysis of product design, which should include inspection items, treatment of key links, etc. In terms of content, it mainly includes the following information:

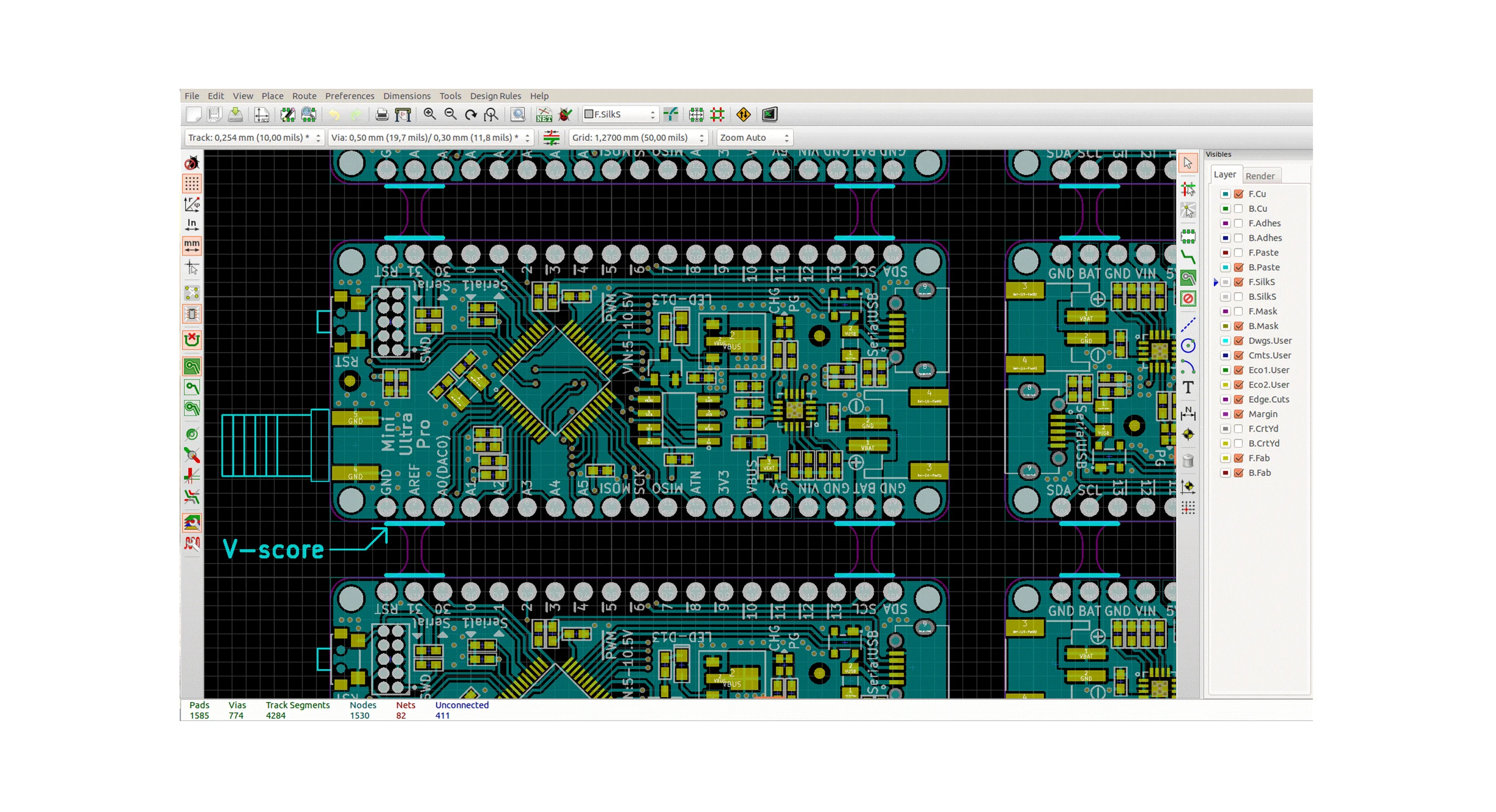

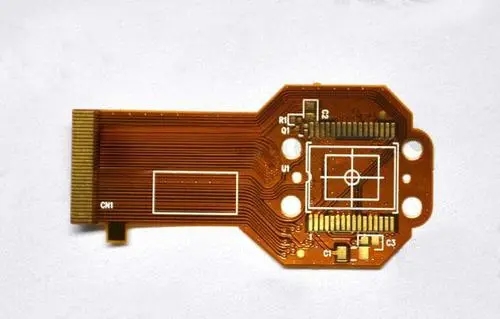

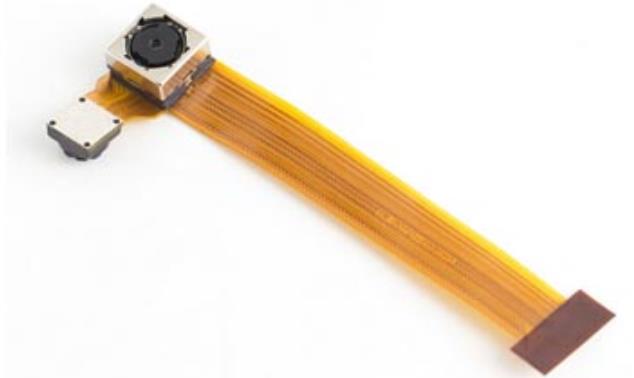

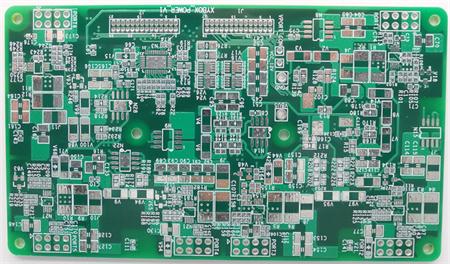

a. Product information and data (such as circuit schematic diagram, PCB diagram, assembly drawing, CAD structure file, etc.)

b. Select the general processing flow of production and manufacturing: AI, SMT, wave soldering, manual soldering, etc.

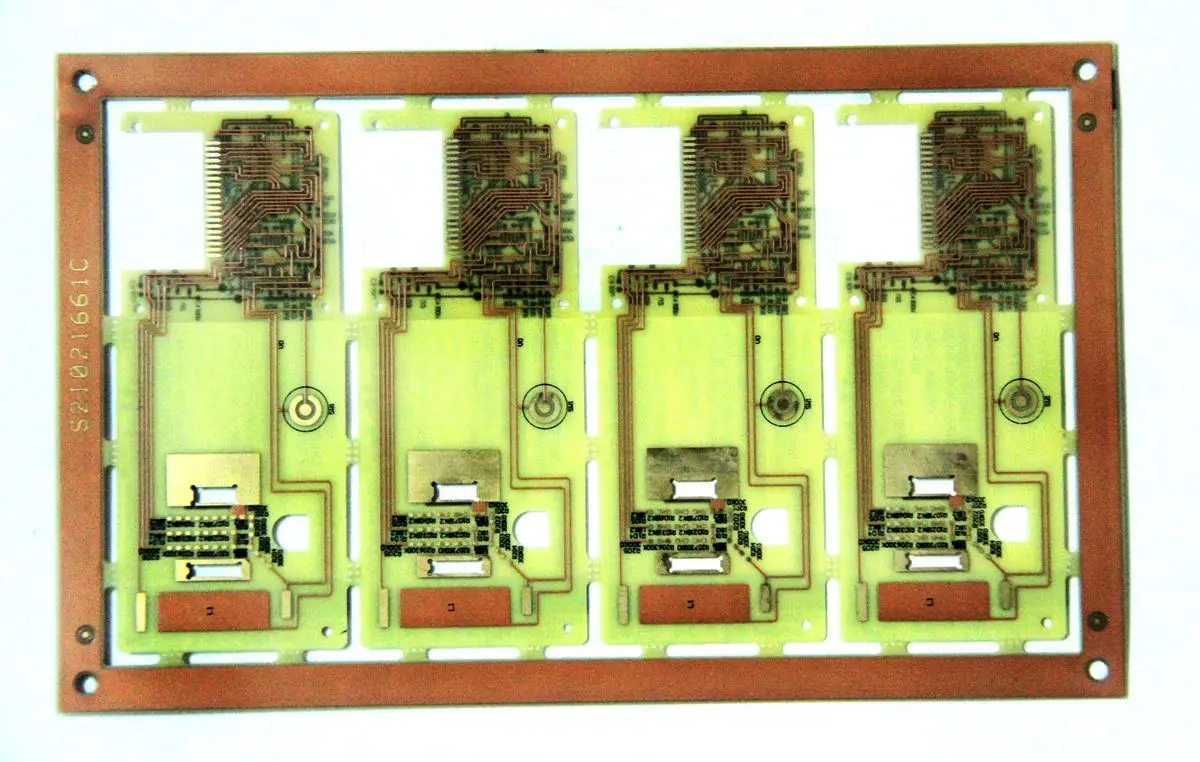

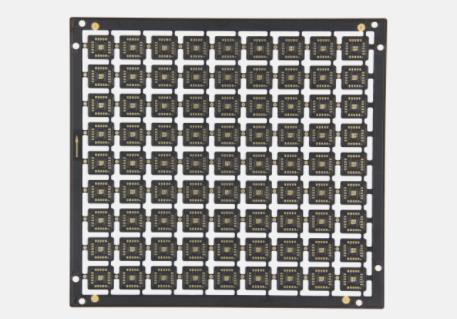

c. PCB size and layout.

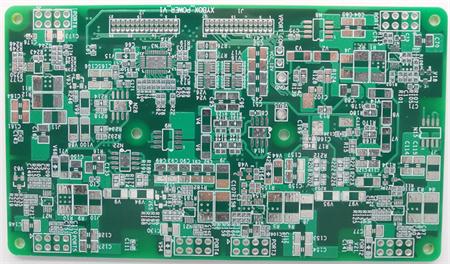

D. Selection of components and parts and design of bonding pad and through-hole.

e. Applicable to the design of process edges, positioning holes and reference points.

f. Implement the requirements of mechanical assembly.

3. Make DFM report: DFM report reflects problems found in the whole design process. This is similar to the audit report in ISO9001. It is mainly based on DFM specification documents and checklists to issue nonconformities in the design. The content must be intuitive and clear, and the reasons for nonconformity should be listed, or even the requirements for correction results can be given. The report is timely and runs through the whole design process.

4. DFM test: how much will the DFM design result affect the production and assembly, and what role it plays. This should be confirmed by DFM test. DFM test refers to the design and testing personnel who use the production process similar to the company's production mode to establish the design samples. This may sometiMES require the help of the production personnel. The test must be fast and accurate and the test report must be made, so that the designer can immediately correct any problems detected and speed up the design cycle.

5. DFM analysis and evaluation: This process is equivalent to summary review. On the one hand, the DFM reliability of product design can be evaluated, and on the other hand, the manufacturing of non DFM design can be simulated and compared with that of DFM design. From the analysis of production quality, efficiency, cost and other aspects, the cost savings of DFM can be obtained, which plays a reference role in formulating annual production goals and capital budgets. On the other hand, it can also strengthen leaders' determination to implement DFM.

Significance of DFM

1. Reduce costs and improve product competitiveness. Low cost and high output are the eternal goals of all companies. By implementing DFM specification, we can effectively use the company's resources to manufacture products with low cost, high quality and high efficiency. If the design of the product does not conform to the production characteristics of the company and the manufacturability is poor, it will take more manpower, material resources and financial resources to achieve the goal. At the same time, we have to pay a heavy price of delaying delivery, or even losing the market.

2. It is conducive to the standardization and automation of production process and the improvement of production efficiency.

DFM organically links the design department with the production department to achieve the purpose of information exchange, so that the design development and production preparation can be coordinated. Unified standard, easy to realize automation and improve production efficiency. At the same time, it can also realize the standardization of production test equipment and reduce the repeated investment in production test equipment.

3. It is conducive to technology transfer, simplifying product transfer process, and strengthening cooperation and communication between companies. At present, many enterprises are limited by the production scale, and a lot of work needs to be processed outside. By implementing DFM, manufacturing technology can be smoothly transferred between the processing unit and the unit to be processed, and production can be organized quickly. The universality of design for manufacturability can make enterprise products realize global production.

4. Basis of new product development and testing.

There is no appropriate DFM specification to control the product design. In the late stage of product development, or even in the mass production stage, this or that kind of assembly problem is found. At this time, if you want to correct it through design changes, it will undoubtedly increase the development cost and extend the product production cycle. Therefore, in addition to focusing on function first, DFM is also very important for new product development.

5. It is suitable for the increasingly complex challenges of new technologies in electronic assembly process.

Now, the development of new technology of electronic assembly process is becoming more and more complex. In order to seize the market and reduce costs, the company must use the latest and fastest assembly process technology to develop, and can keep pace with its development through DFM standardization.

This is the introduction to the design for manufacturability of PCB.

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱